5 Ways To Reduce Turbo Lag

Due to a greater emphasis on fuel efficiency and emissions in the past few years, even lesser performance cars like the Abarth 124 have converted to turbocharging to follow the downsizing trend. With manufacturers becoming obsessed with turbocharging to make up a performance gap, the scourge of turbo lag has now become a large factor in powertrain development.

So what is turbo lag?

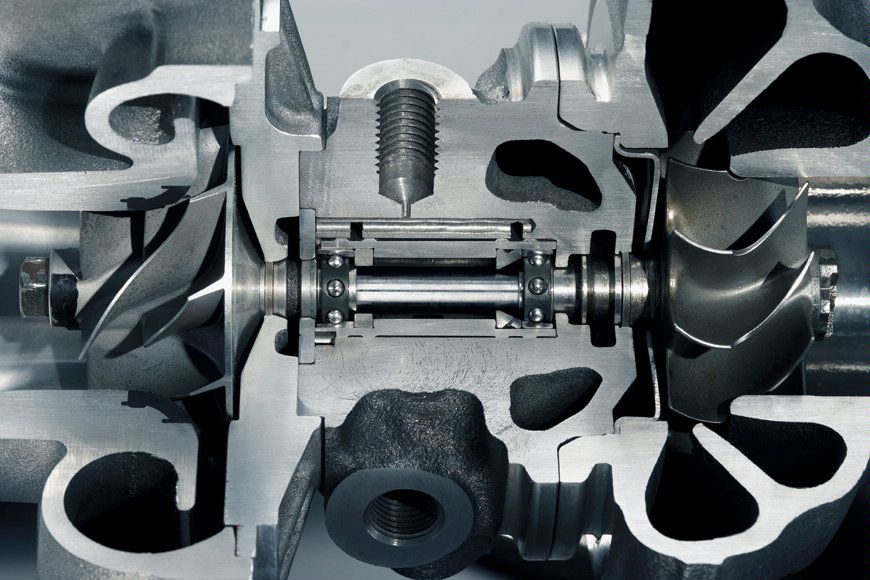

Turbochargers work intrinsically with the flow of exhaust gases which reach a pressure and velocity to spin an impeller (or turbine) within the turbocharger to force air into the cylinders at a faster rate, increasing power. So as engine speed rises, exhaust gas flow increases along with the rate that the impeller spins.

Unfortunately, this means that a time gap forms as the exhaust gases have to make their way from the cylinder, out through the manifold and into the turbocharger. Turbo lag is therefore defined as the gap between the throttle being actuated and the turbocharger responding, resulting in a lumpy delivery of power. I like to think of it like those paper windmills you’d make as a kid. Stuck in the soil of your garden on a calm day, they’d barely spin at all but in gale force winds they’d become a blur of colourful paper and rotational velocity.

In most modern cars, the turbos have been manufactured and programmed to be as linear in their delivery as possible but back in the 80s and 90s, cars like the Porsche 935 and Ferrari F40 were renowned for their widowing bursts of unexpected power.

So what solutions are there for tackling turbo lag?

Twin-scroll turbos

A twin-scroll turbo effectively brings together twin-turbocharging into one neat package. Using two inlets for the exhaust gases instead of the conventional single inlet, this form of turbo is designed to operate at small and high exhaust gas flow rates, reducing the effects of turbo lag.

The first inlet to the turbocharger is designed for lower engine speeds where exhaust gas flow rate is low and is therefore small in diameter. This will maximise pressure on the impeller blades where most conventional turbos would be struggling to spool. The second inlet is consequently larger in size to deal with a high flow rate of exhaust gases.

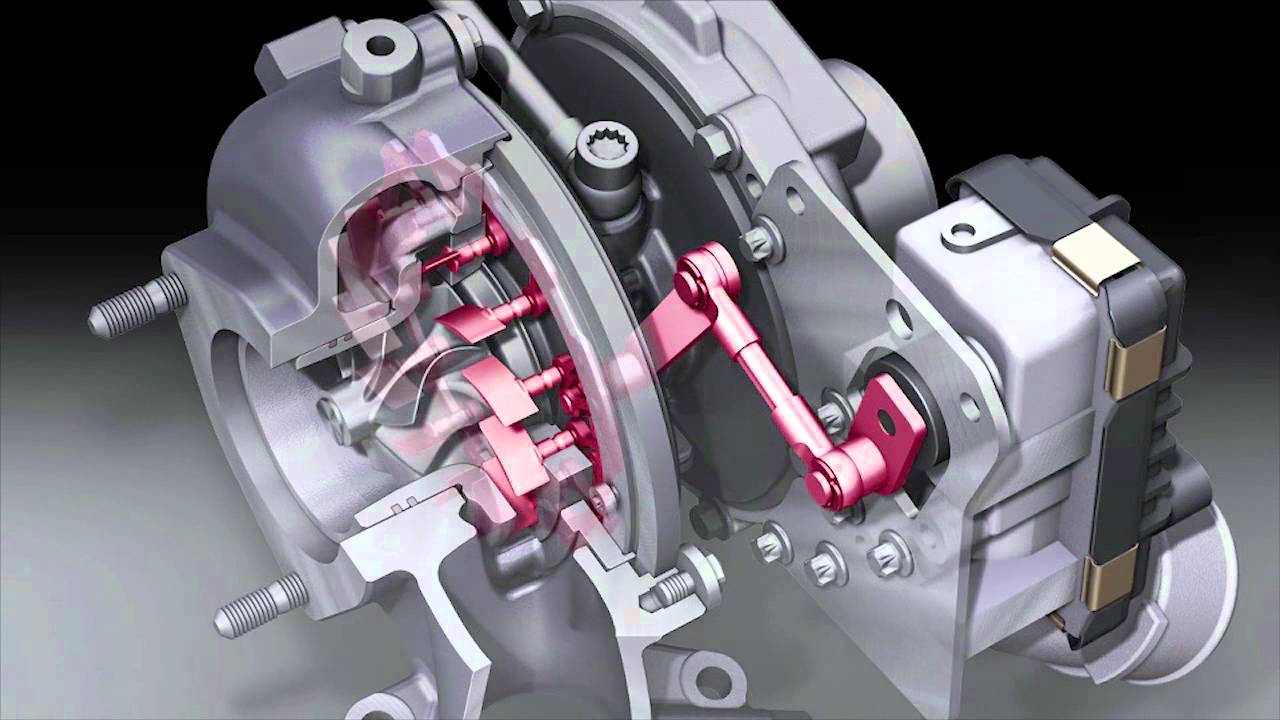

Variable geometry turbos

A more complicated and less-reliable method of reducing turbo lag is VGT. This uses dynamic vanes within the turbo which can open and close their relative angle to the central spinning shaft. This theoretically means that they can close right up to take advantage of lower engine speeds and then progressively open up to then capitalise on the full potential of the vane surface area.

The dangers of this technology is the risk of the vanes failing to open at the same rate as the increase in engine speed. If they were to stay shut, the turbocharger would input too much boost back into the cylinders and high RPM which can easily end up in an engine blowout.

Nitrous

NOx is used to make the pressure within each cylinder go through the roof. Since that pressure is directly related with exhaust gas flow, the introduction of Nitrous to the combustion process makes for an instant pressure increase which will translate through to the blades of the turbocharger, creating an instant and rapid spool. On the other hand, if you plan on your engine and turbo lasting anything past the next month or so, I’d advise you stay clear of this tempting but car-busting substance.

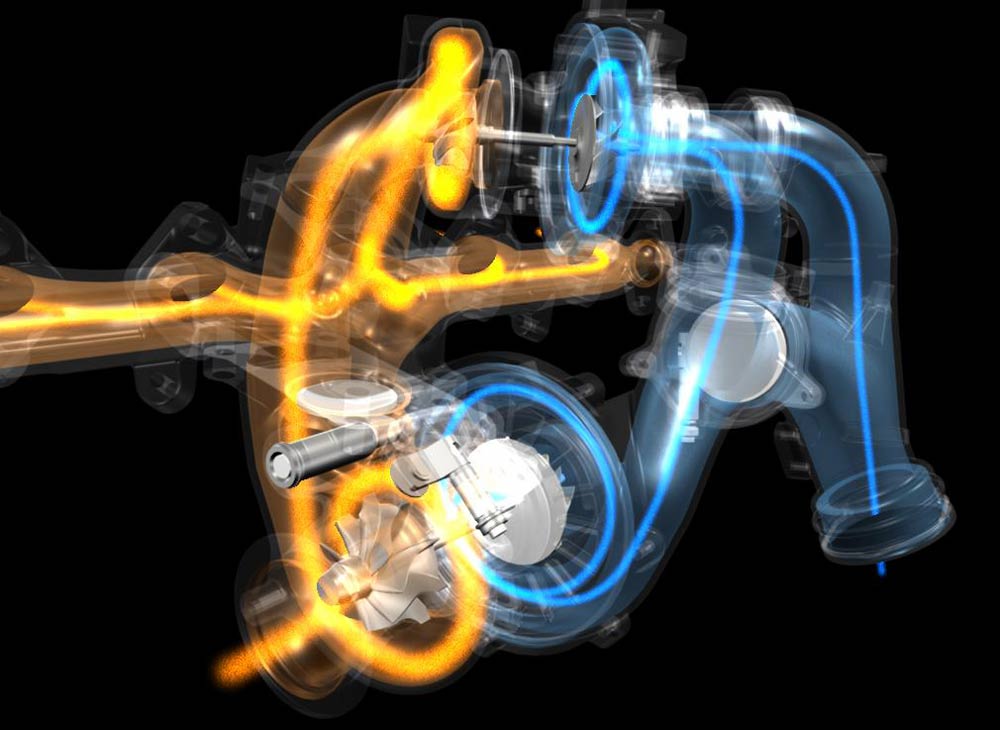

Sequential turbos

Two is normally always better than one and the same can be said for turbocharging. One small turbo and one large turbo work together to keep the engine boosted at as wide a range of RPMs as possible, reducing turbo lag. The small turbocharger only needs a small amount of inertia to get spooling and therefore boosts the engine at lower engine speeds. As the engine speed rises, the larger turbo is then introduced, using its larger vanes to increase the pressure of the recycled exhaust gases back into the combustion chamber.

The Mazda RX-7, Nissan GTR and Porsche 911 Turbo all employ this combination of turbochargers to frightening effect. Twin-turbos can be the key to huge levels of power and torque due to the flexibility between turbocharger sizing, hence why twin-turboed Supras - for example - can often be found with well over 1000bhp on tap.

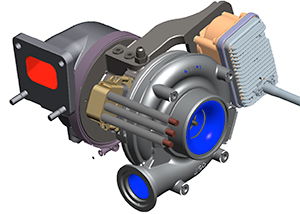

Electric hybrid turbo

With electrics infiltrating nearly every other aspect of motoring, it wasn’t going to be long before they made their mechanical-smiting way into turbocharging. Using an electric motor between the inlet and outlet of the turbocharger, a load is applied through the central shaft of the turbo to keep it partially spooled and ready for the exhaust gases to catch up and take over the spooling process.

Used primarily in Formula 1, the engine is constantly on boost even when exhaust gas flow is slow, making turbo lag extremely minimal. The Audi SQ7 stakes the claim for the first road car to use electric turbocharging and it won’t be long before this technology is made more affordable and could dominate this new world of obsessive forced-induction.

But are these solutions for the best?

Old school turbocharging will often lead to a car being left at the lights before it has a chance to spool up its turbos. Although the power delivery from a heavily turbocharged powertrain can be addictive, it can also be frustrating in comparison to the instant throttle response of a naturally-aspirated or supercharged engine. Manufacturers like Lancia even went as far as both turbocharging and supercharging their engines (like on the Delta S4) to maximise power and eradicate any lag but the sheer strength needed in the engine block to cope with that combination is often deemed by engineers to be not worth the hassle.

Although these solutions have almost eradicated turbo lag from cars like the Porsche 911 and McLaren 570S, waiting for a sudden surge in power can give a car so much more character and can therefore leave modern turbocharged powertrains feeling slightly numb and unexciting. There’s no doubt that they are capable, but sometimes a little old school is no bad thing.

Comments

I say keep them naturally aspirated but make them petrol-electric hybrids. No lag, MUCH more torque, more overall power, more fuel efficient, and you’ll even get a tax break!

This should be renamed “10 ways to reduce turbo threshold”

If you want to reduce turbo-lag, increase power and also make your car sound better you can use anti-lag system

Is it possible to use two turbochargers (a small one, and a bigger one) in order to cover both low RPM range and high RPM range? I’ve seen lots of turbo setups, but I’m still wondering!

Hi,

Some confusion here about how a turbomachine works :)

Turbos ability to make boost is more related to the heat you put in than the speed of the flow you put in.

That’s why THE FIRST way to reduce lag with a properly sized turbo, is to keep heat from the engine and efficiently bring it to the turbine.

Simple way to do this are put turbo as close as possible to the valves, reduce the surface area of the exaust port to limit heat dissipation and shield the exhaust system between haed to turbine to keep heat.

All of theses solution are visible in the “In V” bi turbo BMW F10 M5, Head integrated exhaust manifold of the new Focus RS and some other up to date turbo engines

2nd misconception

The twin scroll turbine.

It can work as you stated but firstly and mostly this configuration is for puls separation and that’s why you see twin scroll turbo mostly on 4 pot engines.

On 4 cylinder engine consecutive fireing cylinder can alter cylinder filling …

For exemple when the cylinder n°2 is in overlap (both intake and exhaust valves open) the cylinder n°1 just start to expell hot and still under pressure burned gaz, it’s easy to see that at that time that hot and pressurisez gaz are very nasty for cylinder n°2 fresh mixture suction (even on turboed engine! ;) )

So to acheive a well separated exhaust pulse twin scroll where made and then like in NA engine linked the 180° phased cylinder so the 1 and 4 and the 2 and 3 cylinder pair.

The result is a lot better engine filling so a lot better energie production so a lot more heat available for the turbine and thus a lot less lag as the turbine has enought heat to transform into mechanical work and transforme this into compressor air flow and thus boost.

Another little good move is to allow the turbine to do its job.

As it work like a pressure (and thus heat) drop box which makes mechanical works by doing that just allow it to drop it as low as it can and you can do that by minimising the exhaust back pressure.

In fact there is so low energie (speed and heat) remaining after the turbin that the shorter and freer exhaust, the better for a turboed engine…. just deal with the noize and emission :P

A little Add on about VGT

VGT have a better average efficiency but a noticably less max turbine efficiency du to a bit less free flowing and low surface shape.

And why I don’t see a word about ported shrouded compressor inlet?

Keep going Michael Fernie :thumbup:

Oh and i almost forgot, Nos is not NOx thing …. it’s N2 + O not the same thing ;)

Step 1:

Dont have a Turbo :(

No anti lag? I thought that’d be the first thing on the list

What about Antilag/ 2step?

I’m surprised turbo positioning (i.e “hot V”) wasn’t mentioned!

Mabye get a bigger engine ?

Pagination