Engineering Explained: How Manual Transmissions Work And Why They're Better

Perhaps you’re unfamiliar with the technology. It’s been around for longer than you’ve been alive. Let’s work our way through four basic questions:

- What are the components of a manual transmission?

- How does a manual transmission work?

- What’s the deal with short throw shifters?

- What are the benefits of a manual vs an automatic?

1. The components of a manual transmission

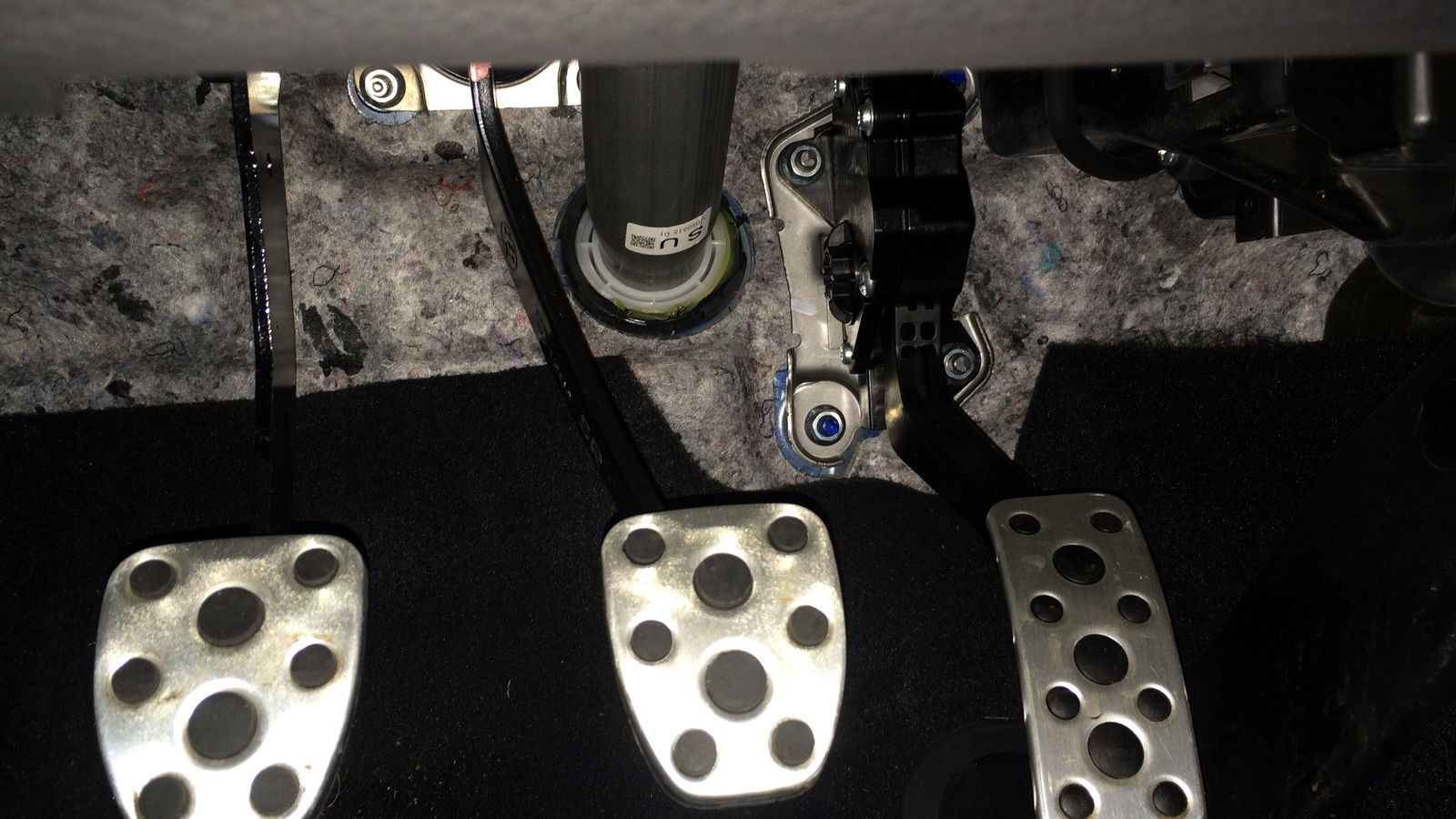

Clutch Pedal:

The infamous third pedal. This disengages the clutch when you depress it. Typically this is controlled hydraulically.

This is a system of components which is used to transmit engine torque to the transmission. It consists of a pressure plate, diaphragm spring, clutch disc, throwout bearing, and other smaller components. The clutch disc is a friction pad which is sandwiched between the flywheel and the pressure plate.

As it relates to manual transmissions, the flywheel is the component which delivers engine torque to the clutch disc. This circular mass has a smooth surface which the clutch disc interacts with.

Understanding how a clutch works is fairly important to understanding the transmission overall. The following video explains it briefly, and includes information on what constitutes as a performance clutch:

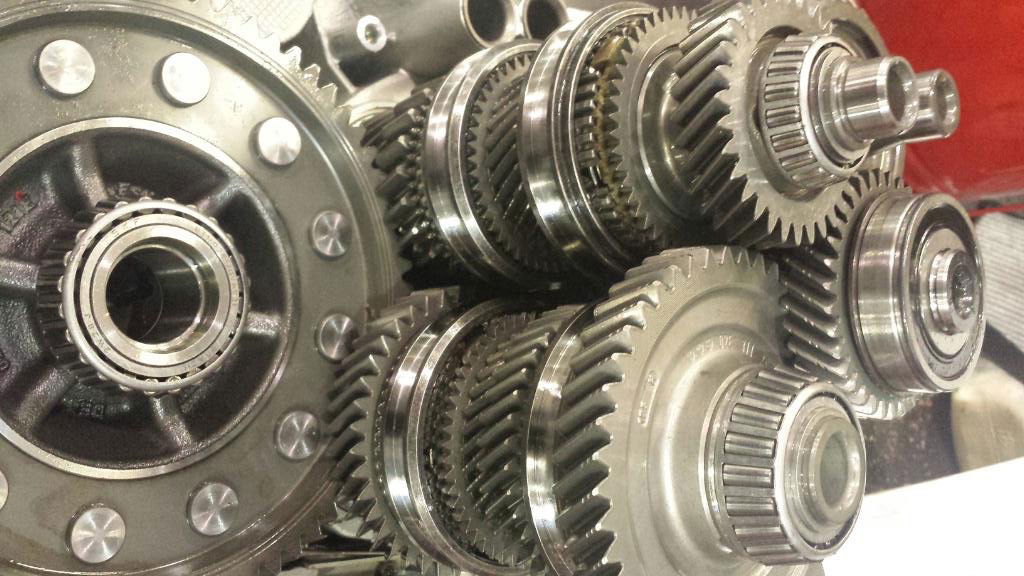

Selector Fork

This arm is used to move the collars along the output shaft (to select gears) and can be moved using the gear shift.

Collar(s)

The collar is what is used to select different gears. It slides between gears, and can mesh with them. The collar is splined to the output shaft, where as the gears rotate with the layshaft (and thus are on bearings on the output shaft). By locking the collar with a selected gear, engine torque passes from the layshaft to the output shaft.

Synchronisers

These are located between the gears and the collar, and allow for the collar to engage the gear even if there is a speed differential between the two. Essentially, this aids in matching the speed of the gear and the collar.

Layshaft

Engine power is directed towards the layshaft, which contains gears which mesh to the gears on the output shaft. This is also referred to as a countershaft.

Output shaft

The output shaft houses the gears, which are on bearings, and thus they rotate with the layshaft. The only time the output shaft and layshaft rotate together is when a gear is meshed with the respective collar, and the output shaft will rotate at the rate at which the engaged gear is spinning.

Gears

Various sized gears are used to allow for different wheel speeds. Larger gears will provide more torque but have lower maximum speeds. Smaller gears (with fewer teeth) will provide less torque, but will allow the car to travel at a higher speed.

2. How does a manual transmission work?

The process of changing gears is as follows:

- With the car at a stop, the clutch pedal is depressed.

- By pressing the clutch pedal, the throwout bearing presses against the diaphragm spring which releases the hold of the clutch disc between the pressure plate and the flywheel. The engine and transmission are no longer directly linked.

- First gear is selected by moving the gear shift into place, which forces the selector fork to mesh the collar between gears one and two into the first gear.

- While applying throttle lightly, the clutch pedal is released gently with the left foot while simultaneously the right foot applies more throttle until the clutch is fully released. Now the car is in first gear (and moving) and the engine and transmission are fully linked.

- The process repeats to change gears. Right foot off the throttle while simultaneously depressing the left foot to disengage the clutch. The gear selector is moved to the second position, pulling the collar out of first and engaging it with the next gear. As the clutch is released throttle is applied, ideally matching the engine speed to the transmission speed so the transition is smooth. The process continues for the rest of the gears.

- When the car comes to a stop, you depress the clutch, place the gear shift in the centre/neutral (thus no gears are engaged), and then release the clutch. It’s best practice to leave the car in neutral rather than having the clutch depressed at a stop, as this can lead to wearing of the throwout bearing.

Here’s a video further elaborating on how manual transmissions work, as well as how they differ from planetary style automatics:

3. What’s the deal with short-throw shifters?

A common modification to manual transmissions is to replace the gear selector with a short-throw shifter. Essentially how this works is the lever arm is changed, and at a cost of increased throw effort, the distance the gear selector travels between shifts is shorter. This is really all about feel and comes down to driver preference. Some may claim that short shifters allow for faster shifting, but the difference will be incredibly minimal if there’s any benefit. Remember, in order for a gearshift to take place, your foot must press the clutch pedal in, and then release it. This is two motions, rather than the singular motion of placing the gear shift into position (it either moves forward or back). In addition, mechanically the transmission operates the same; the synchros will not suddenly be able to mesh faster.

Ultimately, the only thing you’re doing is reducing the distance your hand moves while increasing the force you must press in order to engage the next gear. Is it worth it? Purely depends on what your preference is.

4. What are the advantages of a manual transmission?

You don’t even have to bring up the fact that it’s the most fun to drive to see why manual transmissions are one of the best transmissions out there. The benefits are abundant:

1. Simplicity

It challenging to put into words why simplicity is so important, as long as you don’t take this philosophy too far (did someone say Apple?). Ultimately, a simpler solution to solve a problem is always best. In this case, manual transmissions are often easier to work on, easier to design and manufacture, and often have fewer items which could fault should something go wrong.

2. Cost

Less complexity and fewer materials leads to a lower cost. This is a win for the consumer who is savvy with both of his/her feet, as manual vehicles are often significantly cheaper to buy than their automatic counterparts.

3. Weight

Without bulky torque converters nor the complicated clutch and planetary systems of traditional automatics, the weight savings can be meaningful for manual transmission options. As an example, the manual 2015 Subaru WRX is over 160 lbs lighter than it’s CVT twin (though the auto does have a different AWD system as well). It’s silly to pay more for a car that performs worse; get the stick!

4. Efficiency

Fluid couplings generate heat. Heat is wasted energy. When a clutch is fully engaged, 100 per cent of the torque reaching it passes through to the transmission (hold the technical correction, sure some is lost as rotational inertia). Though modern torque converters can lock up, they are not always locked and thus energy is lost.

5. Bump starting?

No Problem, if you don’t quite have the juice to start your motor with a manual transmission vehicle, you can start the engine simply by moving the vehicle (tell your passenger to push, you’re giving them a ride after all) and popping the clutch. This forces the engine to spin just like a starter motor does, and you can be on your way.

At the very least, take the time to learn how to drive a car with a manual transmission. Don’t be the opening scene of this summer’s post-apocalyptic zombie thriller just because you didn’t know how to move a purely mechanical junker. It’s life or death, ya hear!?

Comments