Engineering Explained: Wastegates, Blow Off Valves And Turbo Flutter

In this article, we’ll look at:

- What is a wastegate?

- What’s the difference between internal/external wastegates?

- What is turbo flutter?

- What is a blowoff valve?

- How do anti-lag systems work?

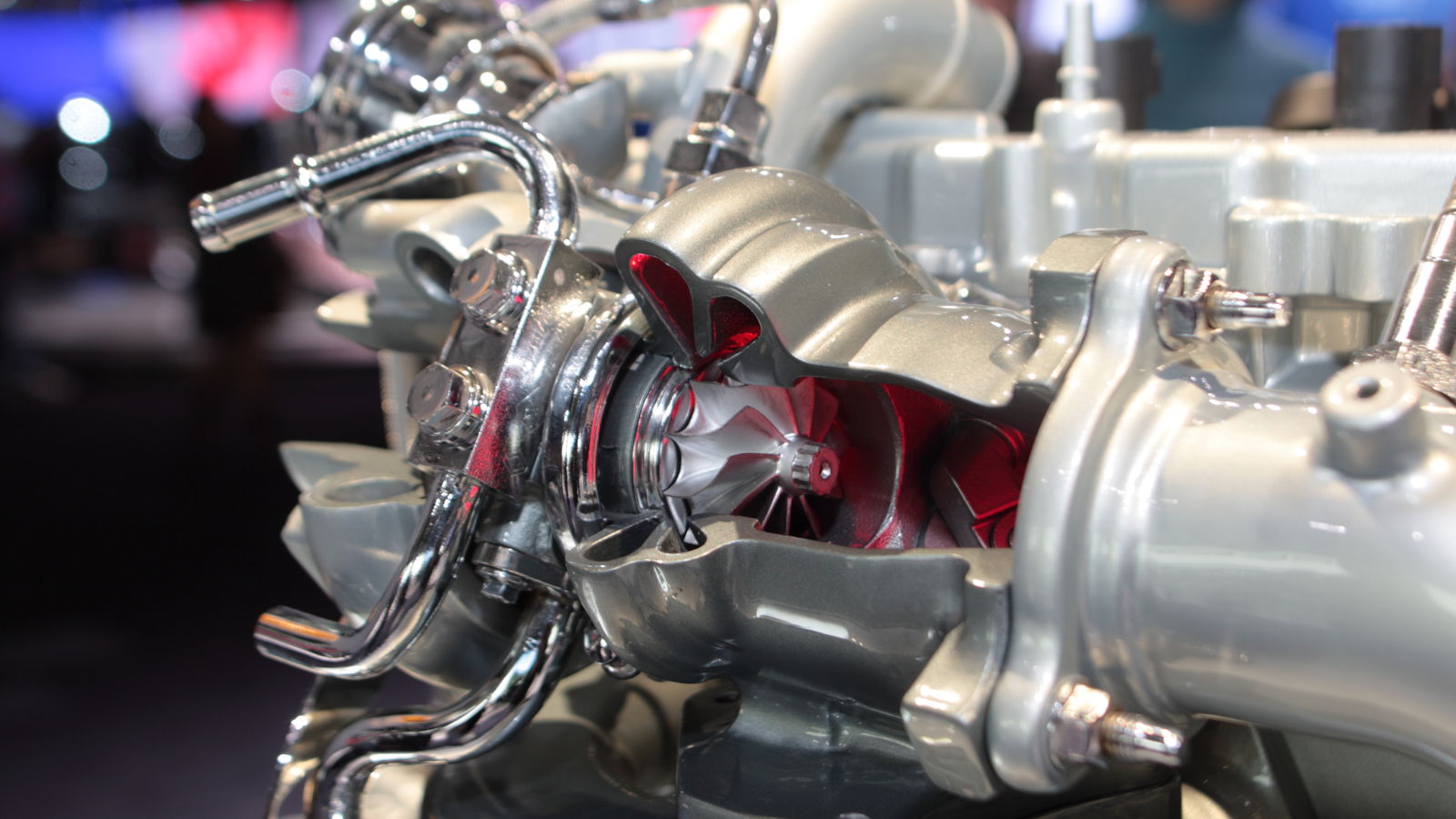

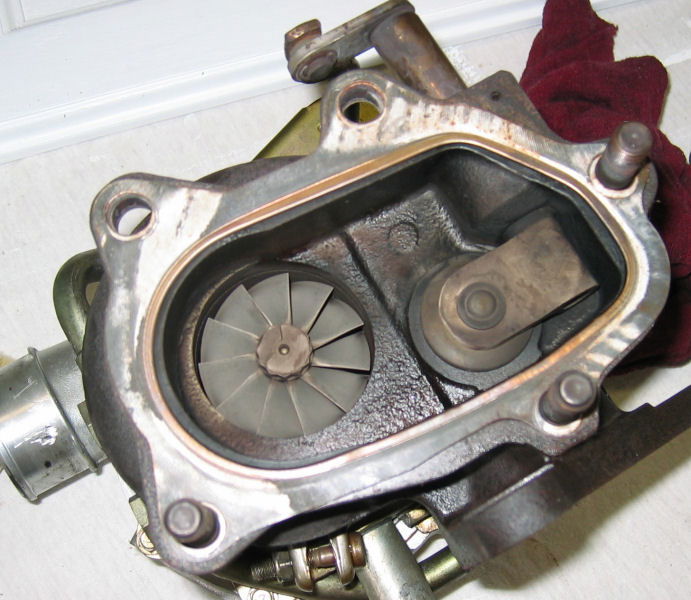

A wastegate is a valve which redirects exhaust gases coming from the engine around the turbocharger so the gases are not used to spool the turbo. This is done to limit the amount of boost an engine creates as to not cause any damage and keep power levels at the desired level. The system works based on pressure. As the intake air reaches a determined level of PSI prior to entering the engine, a spring is pressed open, actuating a valve which allows the exhaust gases to flow past the turbine. The exhaust gases will choose the path of least resistance, so gas will travel through the wastegate so long as peak boost is held. Without sufficient exhaust gases, the turbo will not be able to increase boost pressure.

2. The Difference Between Internal/External Wastegates

As the name implies, internal wastegates are located within the turbocharger housing itself. The diverted exhaust gas passes just before the turbine, and enters the exhaust in the same location as if it were passing through the turbine. The advantage here is that the packaging is compact, with less piping versus an external wastegate, and the exhaust gases by design enter the catalytic converter, which is a great OEM solution.

External wastegates, on the other hand, are located separate from the turbocharger housing. This allows for the exhaust to rejoin the flow further down the exhaust pipe, enhancing the turbine’s performance. For racing applications without emission restrictions, the exhaust can be routed directly to the atmosphere - an exceptionally loud experience. Having the wastegate mounted externally also allows for more flexibility with sizing.

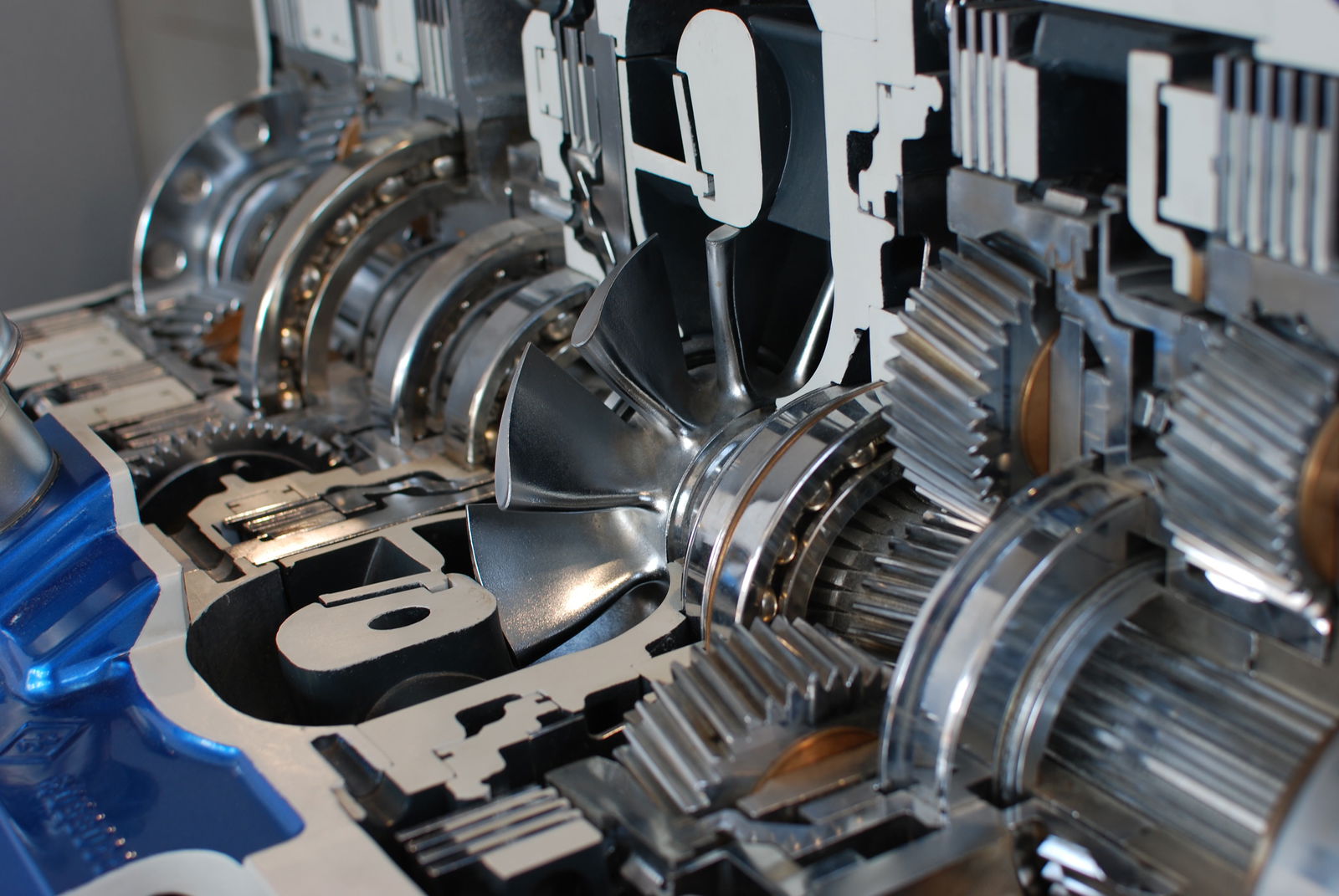

Before getting into blowoff valves, it’s important to understand turbo flutter, also known as compressor surge. When you’re flat out and your turbocharged engine is producing peak boost, you have fast airflow at high pressure traveling through your intake system after the turbo compressor. When you let off the gas, you close the throttle body, momentarily giving you a spike in intake pressure but with no airflow. The air has to travel somewhere, so it heads back through the turbocharger. The fluttering you hear is the air escaping back through the turbo as the compressor wheel fights this motion. Though it sounds awesome, there is no performance nor reliability benefit from this occurring. That’s where blowoff valves come in.

4. What Is A Blowoff Valve?

A blowoff valve (BOV) is similar to a wastegate, except it works on the intake side of the turbocharger. Once a certain level of pressure is reached, the inlet air opens a spring, allowing for the intake air downstream of the turbocharger to either vent to the atmosphere or be redirected back into the turbo. Blowoff valves which open to the atmosphere give the iconic “pssshh” sound, which is heard when you let off the throttle. Instead of the high pressure air trying to work its way back through the compressor (surge), a BOV allows it to escape.

Another interesting way of tackling compressor surge, but also reducing turbo lag, is by using an anti-lag device for turbocharged engines. This operates much like a blowoff valve, except the air is diverted to the exhaust before it enters the turbine. The oxygen rich air meets with the hot exhaust gases, and by running a rich air/fuel mixture in the engine, the air combusts as it reaches the exhaust. This combustion within the exhaust manifold spikes the pressure, keeping the turbocharger spooled while the driver shifts gears. There are other forms of anti-lag as well, for example through ignition delay. By retarding the timing of the spark, you can ensure some of the air-fuel mixture continues to combust while the exhaust valve opens, keeping the turbocharger spooled.

Comments

Thank you so much! I was thinking about a turbo FRS build and this helped me understand turbos a lot more!

I was thinking about turbocharging a 1.6 l to start out. This gave boost to my plans

so a bov is a good thing except the noise

Yeah bro awesome great work Jason! 😃

Hey! Are you a teacher by profession. You teach so well.

Thanks for the article. Was verry helpfull!

Basically stutututututu vs pssssshhhhh

that’s a lot of sucking and blowing!

You always have nice articles and videos, no bs just st8 science with no bias. 4 thumbs up

Pagination