How Do Carburettors Work?

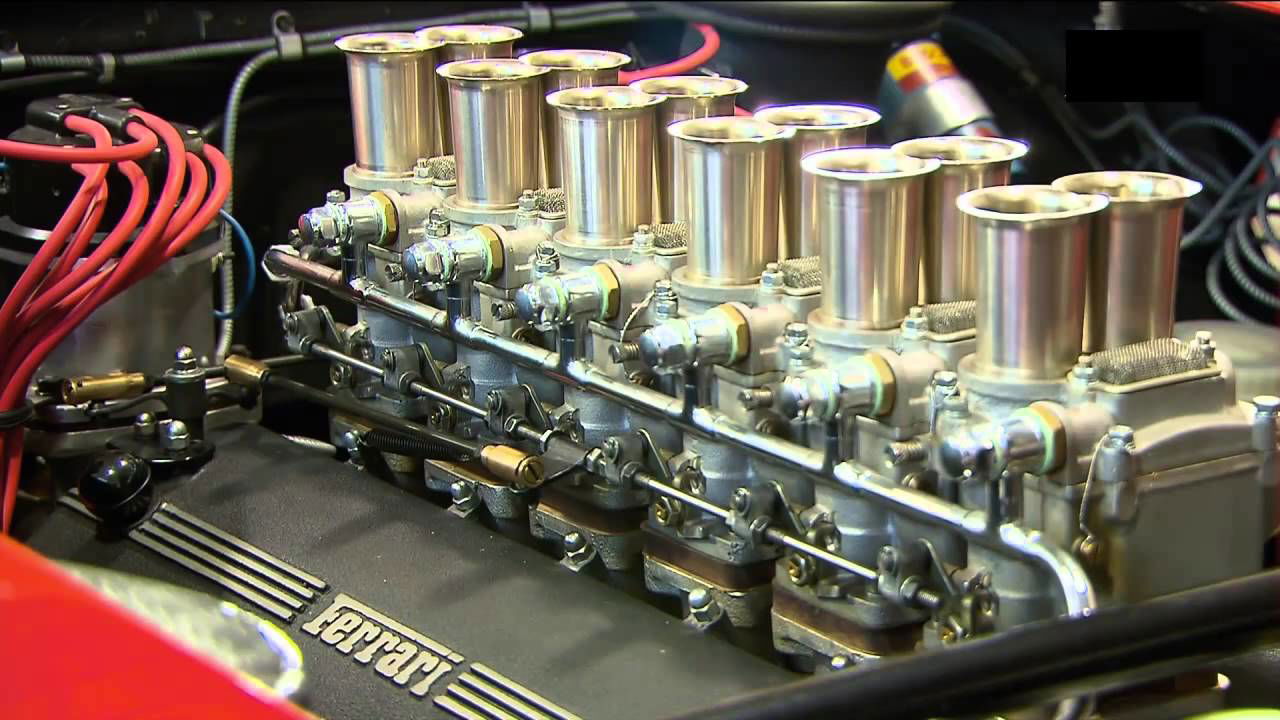

Chances are, if you’re below the age of 25, you’ve probably never come into contact with a carburettor. Fuel injection now completely dominates the automotive world, giving a more consistent and reliable fuel mixture to the engine. But pop back to the middle of the 20th Century and carbs were the norm in almost every motor car, from Austin 1100s to Aston Martin DB5s.

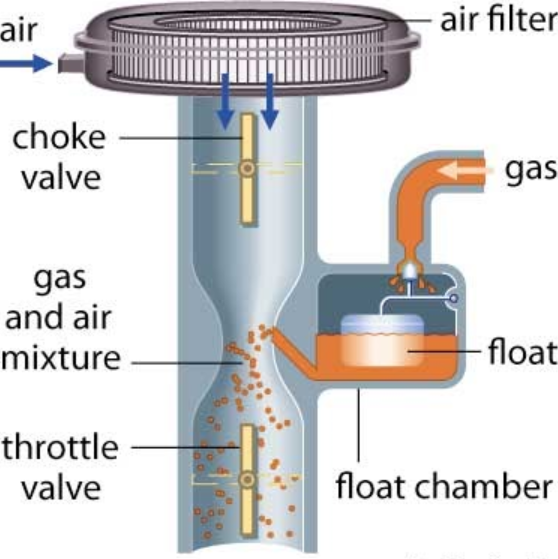

Carburettors are cylindrical components found on the side of older car engines and are used to allow the right air/fuel ratio to enter the engine’s cylinders at a required rate. The basic outline can be seen below:

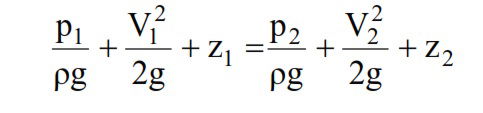

The carburettor works using pressure drops through a venturi and explores a fluid dynamics theory called Bernoulli’s Theorem. Bernoulli basically came up with a pressure balancing equation that proved that fluids will always move from a high pressure area to a low pressure area.

As air is pulled through the air intake, it enters the carburettor and reaches a restriction called a venturi. As the area becomes smaller, the pressure of the air rises, accelerating it out to a lower pressure area on the other side of the venturi. Feeding into the constriction is a small tube - known as a jet - that travels from a float chamber (which contains the fuel) to the air chamber.

Due to the pressure drop created by the venturi, the fuel is sucked from its relative high pressure area through the jet and into the air stream as a spray. The amount of fuel entering the carburettor is then dictated by the difference in pressure from within the float chamber to the end of the jet, which is dependent upon the rate of air flow. The speed of the air flowing through the carburettor is governed by the engine speed and is therefore controlled by a throttle at the base of the carburettor chamber.

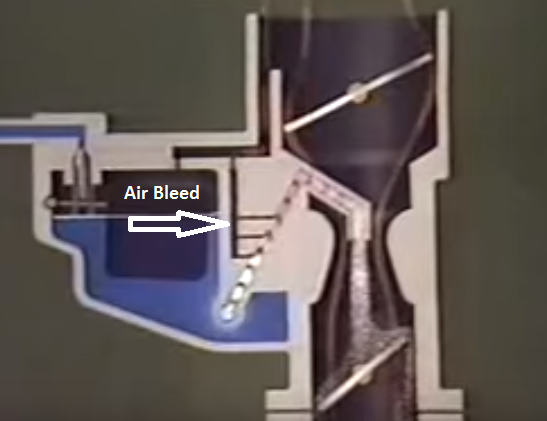

Single-jet carbs were extremely basic in their setup and therefore were modified in the mid-20th century to fulfil the needs of cars on sale. As car engines became more efficient and powerful, carburettor design also had to evolve as more air was needed fed into the system to keep the air/fuel ratio at the desired values.

Therefore, something called an air bleed was integrated into carburettor design which restricted the amount of fuel entering the engine by increasing the amount of air in the ratio. Air was bled into the jet in small amounts to basically pre-mix the fuel entering the air chamber, increasing the air quantity in the ratio.

One of the downsides of carburettors has always been the need for a choke. When an engine is started cold, the air/fuel mixture must be richer to keep the engine turning over, therefore the choke is manually closed at the upper end of the carburettor to reduce the amount of incoming air. This closure also means that the suction created by the pressure drop is concentrated on the inlet of fuel, further decreasing the air/fuel ratio.

Modern fuel injected cars have an automatic choke simulated through a ‘start-up’ fuel map which is programmed into the ECU to create a rich mixture from a cold start, making the operation of a choke non-existent nowadays.

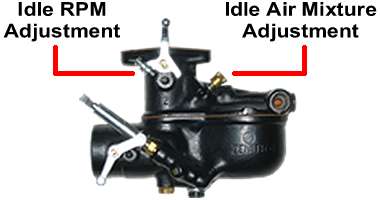

Another problem carburettors had was the lack of air flow when a car was sitting at idle which resulted in a lack of fuel entering the venturi. This had to be solved using an idling jet, which injected a small amount of fuel at the lower end of the carb at the throttle valve. Using a small amount of air sucked from the venturi, a sufficient mixture could be supplied to the engine to keep it turning over at idle. Again, fuel injection systems have been fully developed to eradicate these problems, making the carburettor all but redundant.

Carburettors were developed further and further throughout the mass-production of cars in the last century and in many high performance cars of the time, you will often see double and triple carbs used to cope with the demands of the engine. They were used all the way up until the 1990s, from which time fuel injection was more than capable of taking over the reins. With carburettors being maintenance-heavy due to a constant need for tuning to keep the engine running smoothly, they are very much a thing of the past with the only exception being some very basic cars in developing markets.

But if you ever plan on restoring a classic or simply driving an older car as a daily, hopefully you now know the basics of what is an extremely important component from yesteryear.

Comments

I’m 16 and my Honda has a carb…….it’s a lawnmower

Carbs still live in cycling.

Just different carbs.

I’m 19 and my 65 ford f100 has a 2bbl autolite 6250 series to top my massive 352ci and my 73 Maverick has a single barrel Motorcraft 150ccm to top my original in line 6 200ci

My dad has an 4bbl eldbrock 750ci topping the 302ci in his 65 f100 and an original 2bbl Rochester carb on the 400 in his 72 firebird and my mom has dual weber 40 IDF carbs on the 4 cyl. In her 73 vw type 3 squareback.

23, and my 50cc, my 125cc and my old peugeot 106 have carbs =)

3rd gen Honda Prelude twincarb, explain that witchcraft :D

I own one, I… Yeah, you should know… :/

Not a good article since it lacks alot of information about how carburettors work.

The bike i bought this winter is carb’d. 1999 model. i’m not very skilled in mechanics so i haven’t done much to it yet, good to have a nice detail view into the system though. had me hooked and got me to reading into further details on wikipedia. thumbs up.

Very intresting, I guess you learn something new every day!

This is all so complex….

you better know what you are doing with a carb if you want to extract as much performance as possible from it, and for engines with numerous carbs (like the magnificient 12stacks picture above) its quite hard to get the tune right and ensure every cylinder has the right A/F so they can all produce the same amount of work….and if you plan to do an overhaul on an old carb, newbies(which I am) be warned there are A LOT of small parts in a carb you have to be quite organized to put them all back together

Pagination