How Do Electric Vehicles Produce Instant Torque?

Torque delivery is an aspect of engines that has become a high priority in performance cars in recent years. Customers are wanting maximum torque as quickly and for as long a duration as possible, which has forced manufacturers to look into different ways of manipulating the older technology of the internal combustion engine.

The emergence of electric vehicles in the marketplace has meant that the reputations of even the torquiest IC engines are at risk. With companies like Tesla with its Ludicrous modes and even a BMW i3 beating the previous M3 off the line, let’s take a look at how the new age cars have managed to create such a massive advantage in torque delivery and why us petrolheads should definitely respect the electric motor.

Internal combustion torque delivery

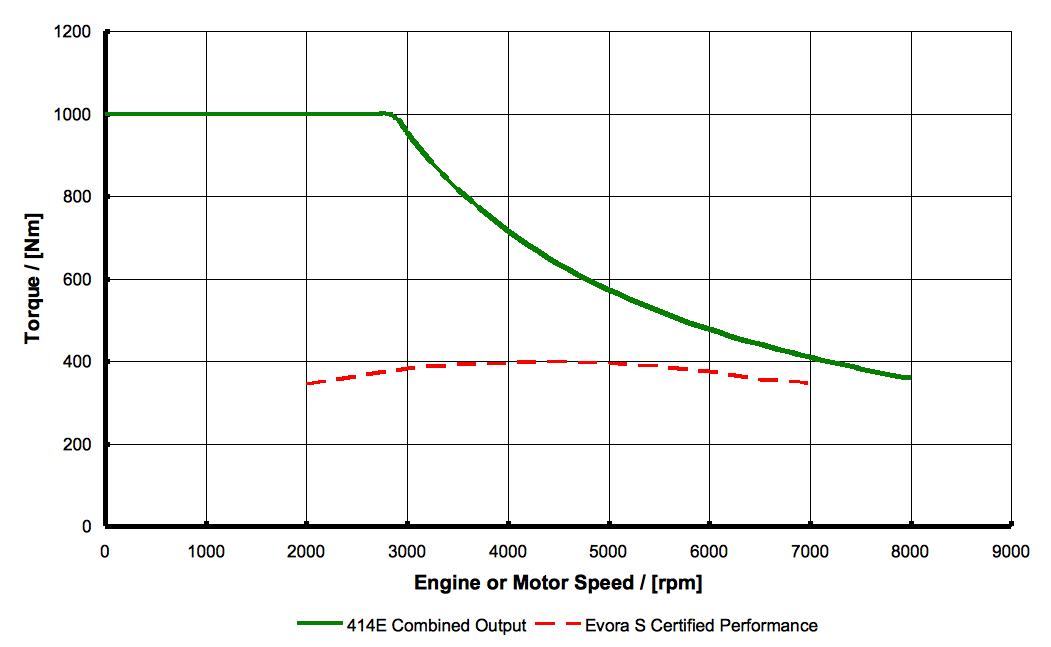

You’ll all be familiar with the look of a torque curve: slowly ascending upwards before peaking and dropping back down; a small mound compared to a power curve’s steep incline. To envisage what is happening in this graph, we should probably look into the engine’s creation of torque.

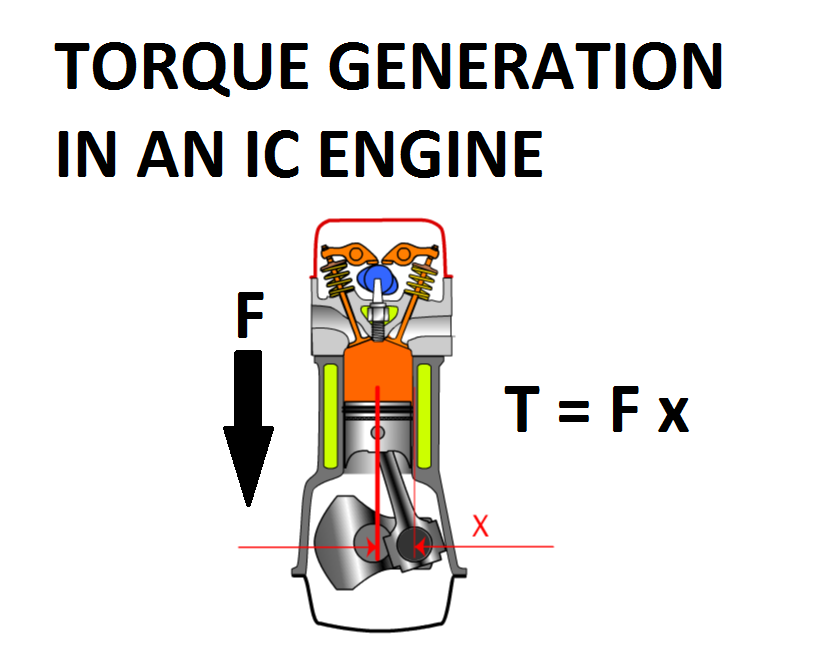

Torque in its most basic form is a turning force and is calculated by a force (F) multiplied by a distance (x). In the case of a piston engine, the ‘F’ is the downwards force pushing the piston vertically and rotating the crankshaft after ignition. The ‘x’ is the horizontal distance between the crankpin and the crankshaft at 270 degrees into the engine cycle. Take a look at the diagram below:

This means that as the size of the explosion increases within the cylinders, the downwards force of the piston also increases, thus increasing the amount of torque produced by the engine. Although it may seem logical that the higher the engine speed, the higher the torque value produced, unfortunately it is not that simple.

One of the main variables that sends a torque curve descending after its peak is the difficulty of forcing air into the engine. The maximum torque will come at a point where the combination of fuel, air and spark coincide to produce the largest vertical force. As the engine speed increases however, it becomes harder for the engine to pull in the required air for combustion using the vacuum of the piston descending in the cylinder after the exhaust stroke. An ECU is programmed to meet the torque needs stated by the manufacturer, with many engines set up to form as flat a torque curve as possible for even distribution across the rev range.

The massive drawback for this torque delivery is the lag in reaching maximum torque. Starting from low RPM, the engine speed has to slowly rise to its maximum torque threshold, which in most naturally-aspirated engines is fairly high in the rev range. Torque gaps inherently exist within the engine map of an IC engine, something that manufacturers have recently tried to minimise with the use of turbocharging and torque vectoring.

Electric vehicle torque delivery

Thankfully, in electric motors, maximum torque is produced from the get-go. As a current flows through the electric motor, a related electrical charge causes an armature to rotate. These rotations within an internal magnetic field cause something called a back-EMF (electromotive force) which opposes the supply voltage. Imagine back-EMF to be the equivalent of a natural braking force, much like in IC engines.

The net overall force being applied to the wheels is therefore the difference between the supply voltage and the EMF. The back-EMF is proportional to speed, therefore the higher the speed, the smaller the net overall force is. This explains why the torque curve begins to diminish on an EV dyno graph as the car’s electric motors are pushed into the upper ranges of their performance limits.

To turn that on its head, if speed is very small (or zero from a standing start), there is little to no back-EMF, meaning that the supply voltage is immediately equated to a torque output. So if you floor the throttle, maximum voltage is suddenly applied therefore maximum torque is immediately available.

With many high-end performance cars now utilising the best of both worlds, the days of the internal combustion engine aren’t quite over yet. The partnerships found in the latest hypercars like the Porsche 918 are massively effective by not only using the electric torque on tap to get off the line but then also bringing in the internal combustion engine to keep that acceleration going. Electrics are then used again to torque fill, culminating in a package built for savage speed.

Although there is something extremely satisfying about keeping a car within its maximum torque band, it seems that for out-and-out performance, the electric motor is the future. With electric-powered vehicles now capable of 0-62mph in under two seconds, the internal combustion engine is well and truly trumped.

Comments

I found the example torque curve for combustion a bit below par. Here is the LT4 curve. Generally only High displacement engines and Bigger Diesel engines have proper low RPM torque. And below 2000revs non of these can compete with EMF

Here is a simple reason..

Pagination