How Much Engine Power Is Lost Through Ancillary Components?

Internal combustion engines are wonderful pieces of kit – somehow a collection of contained explosions in quick succession manages to propel hunks of metal to silly speeds and can extract a series of emotions from us petrolheads. Although its obvious main function is to reciprocate pistons, turn a crankshaft and apply that drive to the drivetrain, the engine also has multiple other chores that need done to keep the car functioning.

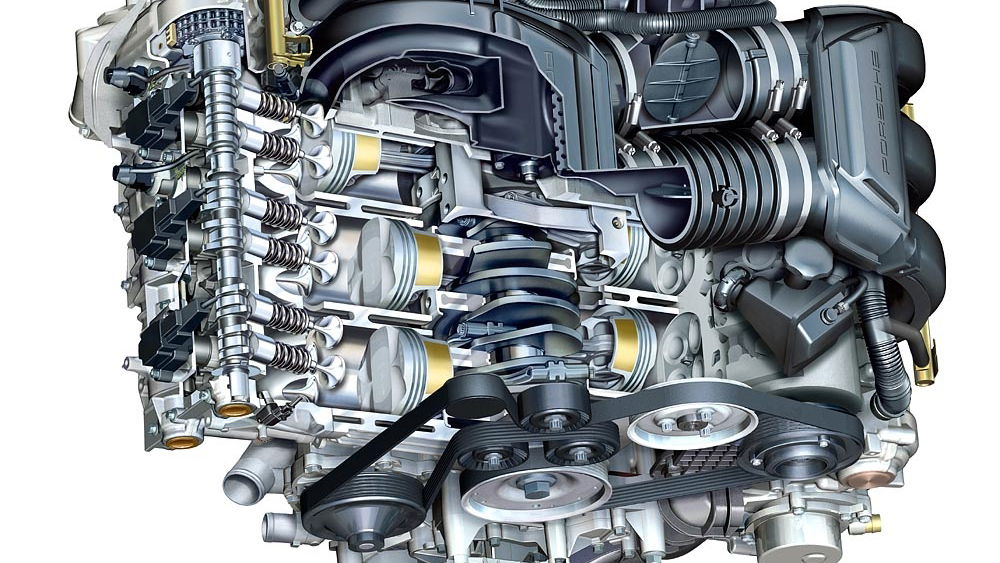

These seemingly trivial tasks are orchestrated normally by one or two serpentine belts which sit at the front of the engine. The key aspect of these rubber belts is that they rotate in tandem with engine speed, forming an intrinsic relationship between specific components that use them and the rate at which the engine is turning. The power needed to rotate the belt is sourced from the engine’s movement which inherently takes a percentage of total power away from reaching the wheels.

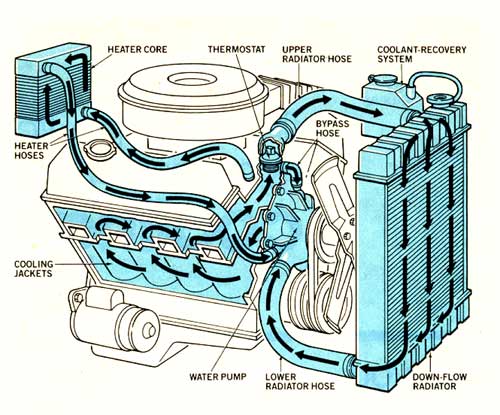

This first component that employs such a belt is the water pump. Used to propel coolant around the engine to transfer heat produced by combustion, it makes sense that this component should work using engine speed. As the amount of combustion cycles increase, more heat will be produced so more coolant interaction is needed. Sadly, this will strip a small amount of power from the engine to rotate the pulley that in turn spins the water pump.

Next comes the alternator which is used to keep the electrical system of the car charged and functional. It does this using the engine’s reciprocation to produce a magnetic field and electric current. Along with stopping your car battery from slowly draining until the car splutters to a standstill, the alternator uses a pulley that is intertwined into the serpentine belt’s routing.

Air-conditioning isn’t intrinsically linked with engine speed but needs a power source to function due to having a compressor within its makeup. This compressor is used to pump refrigerant vapour under high pressure to the condenser from where a cooling air flow can be created for a car’s interior. But yet again it needs a section of the serpentine belt system to allow that compressor to…compress.

The chunk of power that air-con needs is highly debatable and we’ll get onto some estimated figures in a second. The load applied to an engine can be heard when air-con is switched on, with most cars raising their idle speed to counteract the sapping nature of the compressor. The compressor can be brought to life with an electronic clutch that is actuated by switching the air-con on and off.

The final use of a serpentine belt is related to the power steering system. Assuming it isn’t an electric setup we’re talking about, a pump is needed to send hydraulic fluid within the system to apply a force to aid steering and this pump needs a power source to feed from. This is again a pulley that spins to allow the pump to supply pressure to the hydraulic system, resulting in the required assistance.

So how much power is lost through these ancillary components? It’s a sketchy subject because different systems used in different cars by different manufacturers will consume different levels of power from the engine. Thankfully, we can speculate through researching by automotive organisations and other engineering firms.

Air-conditioning is known to sap around 4bhp (calculated by the National Renewable Energy Laboratory) and an alternator of sufficient size will take up around 10bhp (calculated by ZENA, DC motor specialists) when the engine is under full-load. Power steering will set you back more like 2-4bhp depending on the amount of steering input.

For the water pump, things aren’t so simple. Since it shares a relationship with engine speed, the power needed to spin the impeller of the pump forms a cubic relationship with the powertrain’s reciprocation. This was researched by automotive cooling experts Davies Craig that found that its water pumps used 0.13bhp (0.1kW) at 1000rpm, 1.1bhp (0.8kW) at 2000rpm and 8.6bhp (6.4kW) at 4000rpm.

Do the math and you end up somewhere between 16-27bhp of power loss from these ancillary systems depending on the amount of load being applied to each component. The individual power demands of each component will somewhat merge together as the movement of the serpentine belt for one pulley will help the spinning of the next pulley along the system. So in reality the maximum value of power loss should be less than just a straight summation.

Add in around a 15 per cent loss in power through friction, heat and sound that make up drivetrain losses - and the inefficiency of using a rubber belt – and the power being delivered directly to the wheels (whp) can be quite different to that produced originally by the initial internal combustion. Obviously the ancillary components have very important jobs, but there’s something slightly depressing about the amount of power that doesn’t make it to the road surface.

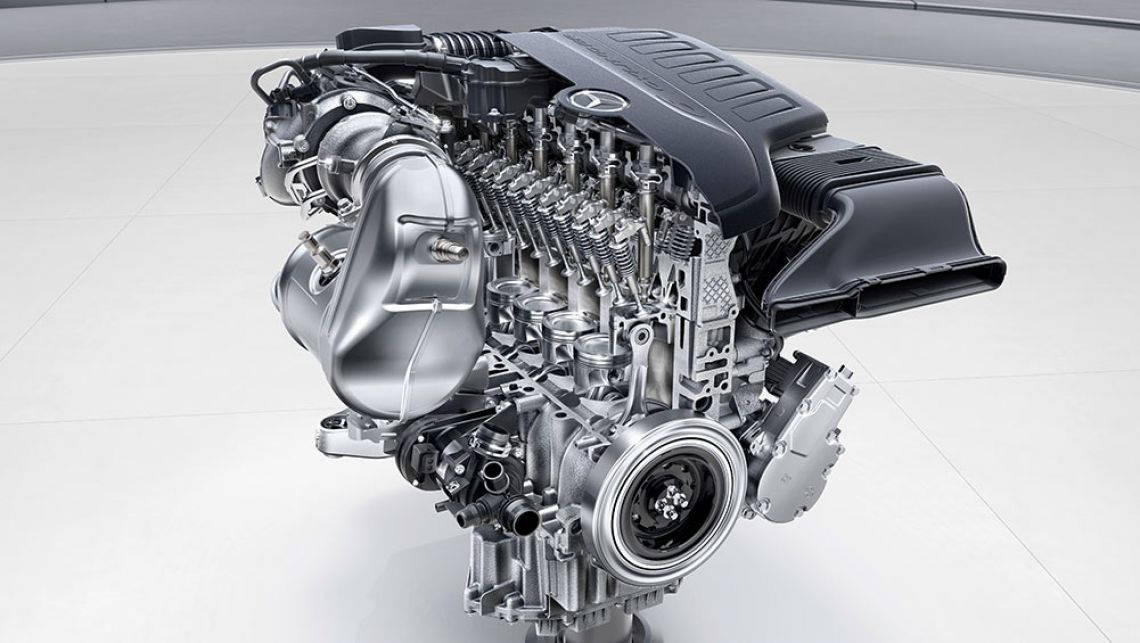

Thankfully, automotive engineers are hell bent on maximising efficiency these days wherever they can, and Mercedes is really pushing this vibe with its latest powertrain. Its new straight-six engine will feature a large 48V battery that will help power the mentioned ancillary components, freeing the engine up to solely provide torque to the crankshaft and through to the transmission.

Using the ECU as its on-board intel, the electric power supply will be able to merge the ancillaries with engine speed, simulating the behaviour of a classic serpentine belt. In future then, we may be rounding those vital horses back into the stable.

Comments

First

Why do I think of this when I hear serpentine belt?

Iwas about to make an Alfa-Romeo joke but you used the Busso V6. Literraly one of the best engine in the world.

So my Clio actually has 90 horsepower. Still junk ._.

Just make more power to begin with, simple.

One reason I love the Beetle is the amount of aux components it uses…

and what does a torque converter do? well it takes whatever you got left from the engine after the other components got their share and then divide it by “imaginary number” and then you can chug along being proud you chose an automatic xD

Hmm, not all cars have serpentine belts… My “fun car in the making” came from factory with - hold on - 4 fanbelts, on of them a ribbed belt. Each belt powers ONE ancillary… ONE powers the altenator, ONE powers the AC compressor (and has a tensioner pulley), ONE powers the water pump (and has a tensioner pulley) and the last ONE powers the power steering pump (but also spinning the viscous clutched fan)… Yay! The joy of 80ies engineering! :D

Sorry for the long post, here’s a potato for those who think it’s TheLADBible.com

Let’s see how many downvotes this comment can get WHATEVER YOU DO DONT UPVOTE THIS COMMENT thanks all

Pagination