The R50/53 Mini Engine Is Part Chrysler, And It's Still Made Today

The use of the term ‘BMW Mini’ or ‘Bini’ for the current Mini hatchback is understandable. The car sits on a BMW platform shared with the likes of the 1-series and 2-series Gran Coupe, is powered by BMW engines, and is stuffed full of BMW technology.

For the original R50, R52 and R53, though, this isn’t really correct. Although BMW had offloaded MG Rover to the Phoenix Consortium by the time of the Mini’s launch in 2001, the company did a large chunk of the legwork for the car. Before the split, there were even plans to build the new Mini at Longbridge. But in the end, BMW kept the project, completed the car and pushed it over the line.

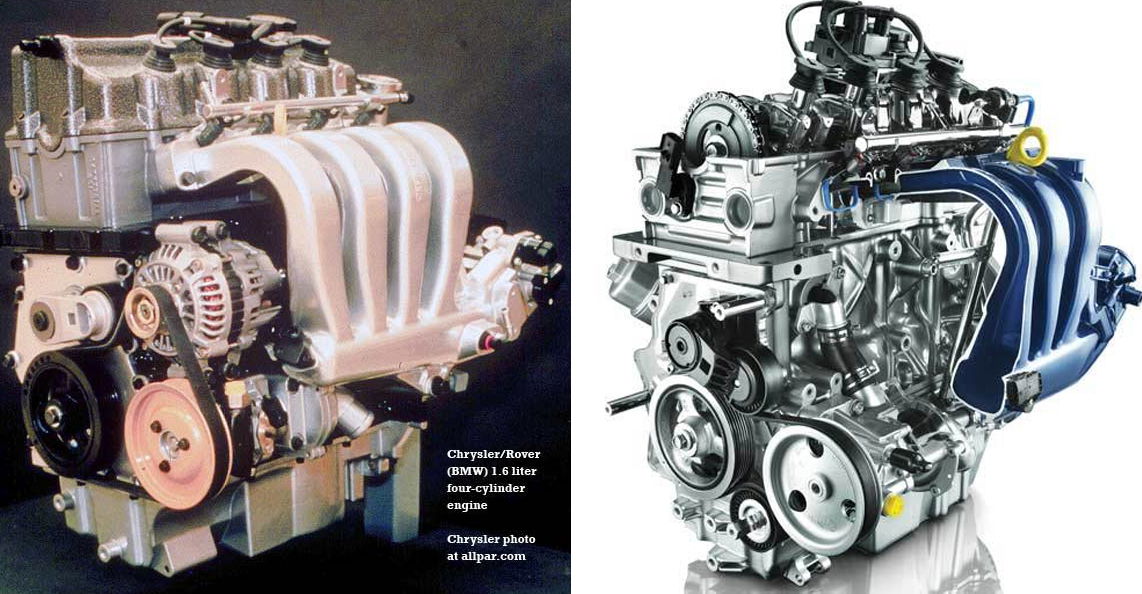

During the car’s protracted development phase, Rover was keen to use its all-aluminium K-Series, but it wasn’t to be. Instead, a joint venture was launched with Chrysler to establish a brand new factory in Curitiba, Brazil. The name Tritec was chosen, representing the three nations that had come together to make it happen - Germany, the UK, and Brazil. $500 million was earmarked to create the 40,000 square metre facility, which had a targetted annual output of 400,000 engines.

Neither the engineers of BMW or Rover were said to be particularly impressed with the engine Tritec made. BMW thought it old-fashioned, while Rover compared the iron-block Tritec unfavourably to the more advanced K-Series with its aluminium block and dual overhead cams.

The single overhead camshaft 1.6-litre unit made a mere 112bhp and 110lb ft of torque even in its pokiest guise. There was also a 1.4 using the same bore but a shorter stroke as the 1.6, although this 73bhp version wasn’t used anything like as prolifically as its bigger brother. A complex engine it was not, but that didn’t matter - with simplicity comes lower costs.

See also: 11 Things You Need To Know Before Buying An R53 Mini Cooper S

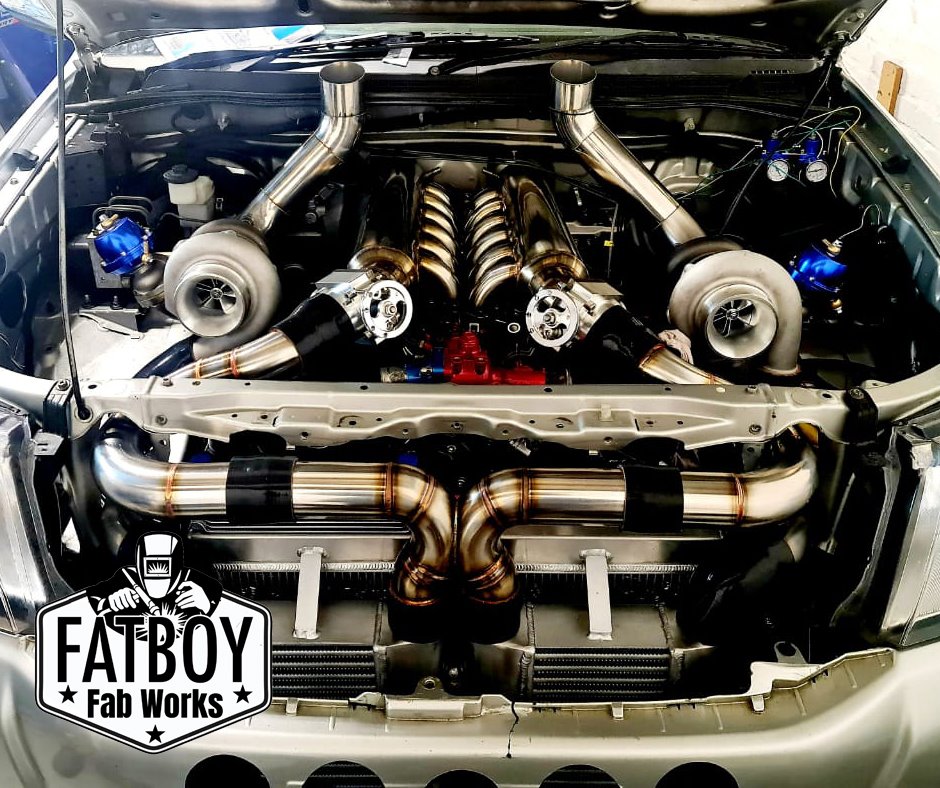

112bhp was right on the money for something like a Mini Cooper, but for the Cooper S, the Tritec engine needed a helping hand. That came in the form of an Eaton E45 Roots supercharger, bumping the output to 160bhp and later 167. Not hugely impressive for a 1.6-litre lump with forced induction, but healthy nonetheless, and the whine of the supercharger gave the Cooper S much more character than most of its rivals.

The Cooper S was the only production car to use the supercharged 1.6. It was adopted by 2006’s Dodge Hornet concept, pitched as a rival to the Mini, which is an unusual story for another time. The naturally-aspirated version meanwhile saw service in a variety of vehicles including the vast majority of the Mini line-up plus various non-US market versions of the Chrysler Neon and the much-maligned PT Cruiser.

Production under Tritec ran from 1999 to 2007. Then, BMW, having retained Rover Group’s 50 per cent Tritec stake since 2000, washed its hands of the endeavour and gave full control to Daimler-Chrysler. This was just before Daimler and Chrysler separated. The latter side of the business was haemorrhaging money, and thus very keen on offloading Tritec, or simply closing it for good.

At the time, Lifan was said to be interested (some of the Chinese manufacturer’s cars did use Tritec engines), but in the end, Tritec was sold to Fiat, some years before the Italian manufacturer merged with Chrysler. Fiat then pumped tens of millions of euros into the factory to allow it to produce a new 1.8 alongside the existing 1.6. The old-school iron block was replaced with one made from aluminium, and construction of both engines continues today. These Tritec successors are used in a number of different cars, including the Fiat 500X and the Jeep Renegade.

As for BMW, it switched to another joint venture for the R56 Mini, partnering with PSA to produce the ‘Prince’ engine. The all-aluminium, French-built engine relied on turbocharging rather than supercharging in the more powerful models. Longevity can be an issue for these things - Google ‘R56 cam chain death rattle’ if you dare.

The Tritec, on the other hand, has stood the test of time. It’s one of the more robust elements of the R53’s somewhat flakey construction, so it’s perhaps best Rover didn’t get its way with the K-Series. Yes, it’s more advanced, but the unit’s reputation for popping head gaskets isn’t entirely undeserved.

See also: Mini Cooper S R53 Vs F56: What Progress Has Been Made In 20 Years?

The transition to BMW engines didn’t happen until the third-generation ‘F56’ Mini came along in 2013. It was given B38 inline-threes, B48 four-pots, and B37/B47 diesels. The Mini is more of an in-house BMW affair than it ever has been, with joint venture quirks like Tritec and Prince out of the window. But is that a good or a bad thing? We’ll let you argue that one in the comments.

Comments

Can’t quite see the point of having the Mini engine plant in Brazil when the Longbridge Powertrain operation was a perfectly good (and independently viable) plant and BMW opened its excellent engine factory at nearby Hams Hall in 2001.