Icon: Where Broncos, FJ40s And More Go To Be Reborn

Pros

Cons

The vehicles rebuilt by San Fernando Valley firm Icon shouldn’t be thought of as cars. They’re more like cherished watches, cared for by family members to be passed on to the next generation. They don’t have owners: they have custodians.

“The concept is simple,” company COO Sherif Yassa explains to me as we wander around the company’s Chatsworth workshop. “You have some connection to an older car. You learned to drive in it. It could have been found in your father or grandfather’s barn but you never used it. That car means something to you for some reason.”

Selling up would be unthinkable, we agree. But if it’s to be kept, it doesn’t just need to be made useable - it also has to be built to last. “Planned obsolescence? We don’t factor that in,” Yassa says. That’s why, for example, you won’t find any plastic inside the cabins of these cars - only the best materials are used, and it’s all hand-made stuff in there.

For the Icon ‘BR’ Bronco, it starts with a comprehensive tear-down, followed by a thorough transformation. It’d be disingenuous to refer to the results as a ‘resto-mod’ - these cars are effectively reborn to start what Yassa refers to as a “second life.”

Icon sources original Bronco bodies that are as solid as possible, giving staff the best possible base for all the ensuing metal work. Much of the mechanicals, meanwhile, are replaced outright with modern parts. That means the Icon Bronco isn’t going to be to everyone’s tastes - lovers of originality aren’t exactly going to be well served here. But there’s no arguing with the results.

It only takes a quick look around Icon’s workshop to understand how much of an upgrade these vehicles receive. “Imagine a who’s who of the manufacturing world and take the best brands - that’s what goes into these cars,” Yassa says.

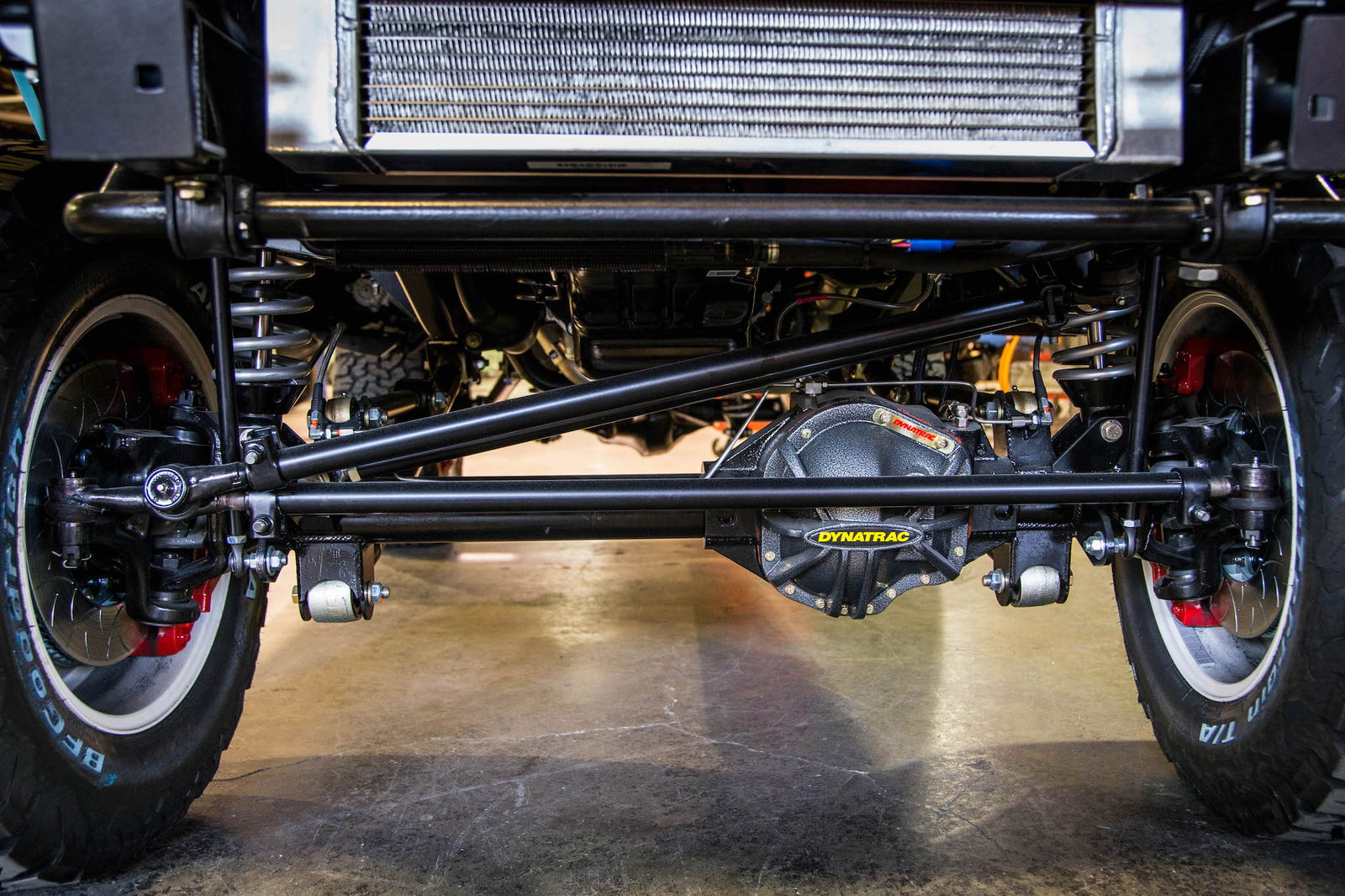

The shock absorbers come from Fox Racing. The engine? That’d be a 5.0-litre Coyote V8 from the Ford Mustang. The axles are made by Dynatrac. The brakes are supplied by Brembo, and they’re anything but off the shelf. “[Brembo] don’t do it for just anybody. They flew out, engineered a system for the Bronco, one for the FJ [FJ40/43/45 Land cruiser], and they do all the one-offs.”

The vehicles gradually progress around the small production line in Icon’s workshop, with the entire build taking about five months for a Bronco and roughly four months for the firm’s reimagined Toyota FJ40 and FJ43 Land Cruisers.

With the average BR build weighing in at $225,000 it’s an expensive business, and it’s an exclusive one too - only 45-50 cars pass through the workshop every year. This will generally comprise 15 Broncos, 15 FJs, 5-7 conventional FJ restorations via the ‘TLC’ side of the business and a smattering of more bespoke projects.

"Icon has a no limit philosophy. We go anywhere the client wants to go."

TLC effectively kicked this whole thing off. Started by husband and wife team Jonathan and Jamie Ward in 1996, TLC’s work soon caught the attention of Toyota itself. Jonathan Ward became involved in various special projects for the company, culminating in the creation of a trio of prototypes which evolved into the FJ Cruiser.

This led to Ward contemplating how the FJ40 could be redesigned for the modern age, and thus, Icon was born. The Bronco followed and later the TR - a modernised Chevrolet Thriftmaster pick-up - and now, there are 50 people working tirelessly in Icon’s Chatsworth facility. There are further sublets working exclusively for Icon too, creating parts like the beautiful bespoke trim pieces in the reinvigorated cabins of these cars.

As for the bespoke stuff, the world’s your oyster. “Icon has a no limit philosophy. We go anywhere the client wants to go. You’re in unchartered territory; you’re doing something that hasn’t been done before,” Sherif says. Naturally, these projects take a little longer, and you’ll have to wait in line longer than anyone queuing up for an FJ, BR or TR.

“We begin with a rendering, then it goes to the design team. Once the client approves that, it goes into engineering.” It’s here that the feasibility is worked out - will the customer’s chosen engine fit? Will the requested brake and suspension setup work with the donor car?

Once all this is answered, the green light is given, and work can begin on something truly special. These ‘Reformer’ projects undergo a similar transformation to the FJs, BRs and TRs, only here, the customer decides what the starting point is and what goes into it.

Previous projects include a 1965 Jeep Wagoneer, a 1965 Dodge Power Wagon, a Land Rover Defender 90, and even an ex-police Chevrolet Caprice. Some are left looking completely standard on the outside, while others are given aesthetic upgrades that hint about the transformation which has gone on underneath.

Derelict projects have a similar ethos, the big difference being that the exteriors of these vehicles are kept original, usually with the patina of the donor car not just retained, but preserved (something you can have done to the BR and TR too, if you want). Headline-grabbing examples have even featured electric powertrains, arguably giving a more intriguing blend of the past and the present than anything else Icon does.

Walking out of Icon’s warehouse into the bright California sun, I’m presented with something I’d missed on my way in. At the far end of the car park is a veritable feast of classic and modern classic metal - Land Cruisers of all generations, Broncos, Thriftmasters, all in varying states of repair.

It’s exciting to ponder what these cars might go on to become. Some will be restored via TLC, others will go through an Icon ‘rebirth’, and a few will go on to become Reformer or Derelict creations, with the owners’ wildest dreams translated into reality.

How I wish one of them was mine…

Comments

First

The OG offroad kings