Monotube Vs Twin-Tube Dampers: How Do They Work?

Sometimes you’ll notice specific references to monotube and twin-tube dampers. They’re both built to do the same job of absorbing the energy transmitted upwards from bumps in the road, but they’re surprisingly different in construction.

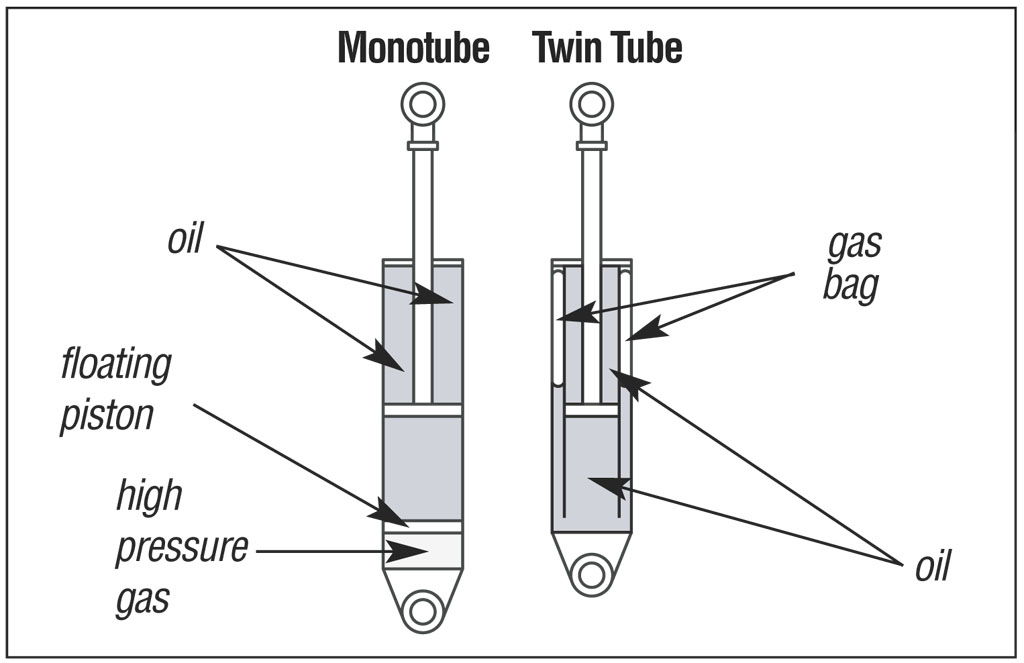

Let’s start with twin-tube dampers: this older style is easier to manufacture and more common as a result, but neither of these things means it’s not a very effective design. The basics of how twin-tube dampers are built involves two tubes (duh), one within the other. The inner tube houses the main oil reservoir within which a piston travels, more of which is explained in our main dampers feature.

When the suspension is compressed, the piston forces oil out of the inner tube via a valve and into the reserve tube. When the piston moves back, the reverse happens; oil is sucked from the reserve tube to the inner one.

Twin-tube dampers have been developed in various ways over the years. Arguably the most significant is gas charging. Either air (cheap and basically effective) or nitrogen (expensive but better) is inserted at low pressure into the outer tube far enough above the valve that it can’t escape into the inner tube accidentally. Its purpose is to keep pressure on that end of the oil volume, minimising the aeration – or ‘foaming’ – that can occur in a twin-tube damper under hard use.

Some manufacturers have a crude way of adding an element of small-bump sensitivity to twin-tube dampers while maintaining large-bump capability. It involves setting small grooves in the upper and lower sections of the inner tube’s wall, where the piston travels. These effectively slow the piston down and help prevent a bottom- or top-out scenario while leaving the central portion of the damper stroke free to move easily over smaller bumps.

Monotube dampers were an innovation from Bilstein in the 1950s. Longer than a twin-tube setup, they place the oil reservoir and a high-pressure gas charge in a line inside a single shell. A ‘floating’ piston separates the liquid and gas. The main damper piston pushes through the oil as normal, but instead of pushing oil into a separate chamber the liquid passes through valves in the piston itself.

This arrangement allows the gas itself to become a greater part of the spring action. It compresses slowly over smaller bumps and more quickly through bigger hits, theoretically improving control and response. Meanwhile the oil reservoir is sealed and can’t foam, although it can experience cavitation. Another potential advantage for ground-up builds or serious suspension projects is that monotube dampers can be used either way up, unlike most twin-tube ones.

It’s worth noting that coilovers can be either twin-tube or monotube, but most common fitments need to be shorter and adopt a twin-tube system. Both designs can offer great suspension performance, though, so whichever setup is right for you, just make sure it’s the best you can afford.

d.jpg?aspect_ratio=1:1)

Comments

I just love these articles.

very good Article but in School we were taught that “Shock Absorbers” don’t absorb Shocks or Bumps but they actually dampen the Oscilations or impulses from the Springs. The Springs in turn do absorb Shocks and Bumps but without the Absorbers the Car would just bounce around like a bit of Jelly, you can see that on Cars with broken Shock Absorbers.

BTW: As usual, in the German Language wie use the Term “Stossdämpfer” (Shock Absorber) colloquially and the Technical Term is “Schwingungsdämpfer” (Oscilation Damper).

I love when i go on snap chat and tbey have some story about cars and they ask stupid stuff like “What makes vtec so awesome?”

hey man, if you need some photos from construction or assembly of both types, just let me know. i can send you some. i work as a technician in production of dampers.