The Problem With Rotary Engines: Engineering Explained

They’re compact, powerful and they make an awesome noise. So why did rotary engines never really take off, and why has the concept been all but abandoned by the one manufacturer that championed it? Let’s take you through it.

The 1964 NSU Spider was the first production car in the world to melt the rear tyres under the power of a Wankel rotary engine. The Wankel’s automotive debut was decades in the making, though its lifespan was relatively short ending with the 2011 Mazda RX-8. This leads us to several questions:

- How does the rotary engine work?

- What advantages does this engine have? (Why was it made?)

- What disadvantages does the engine have? (Why did it die?)

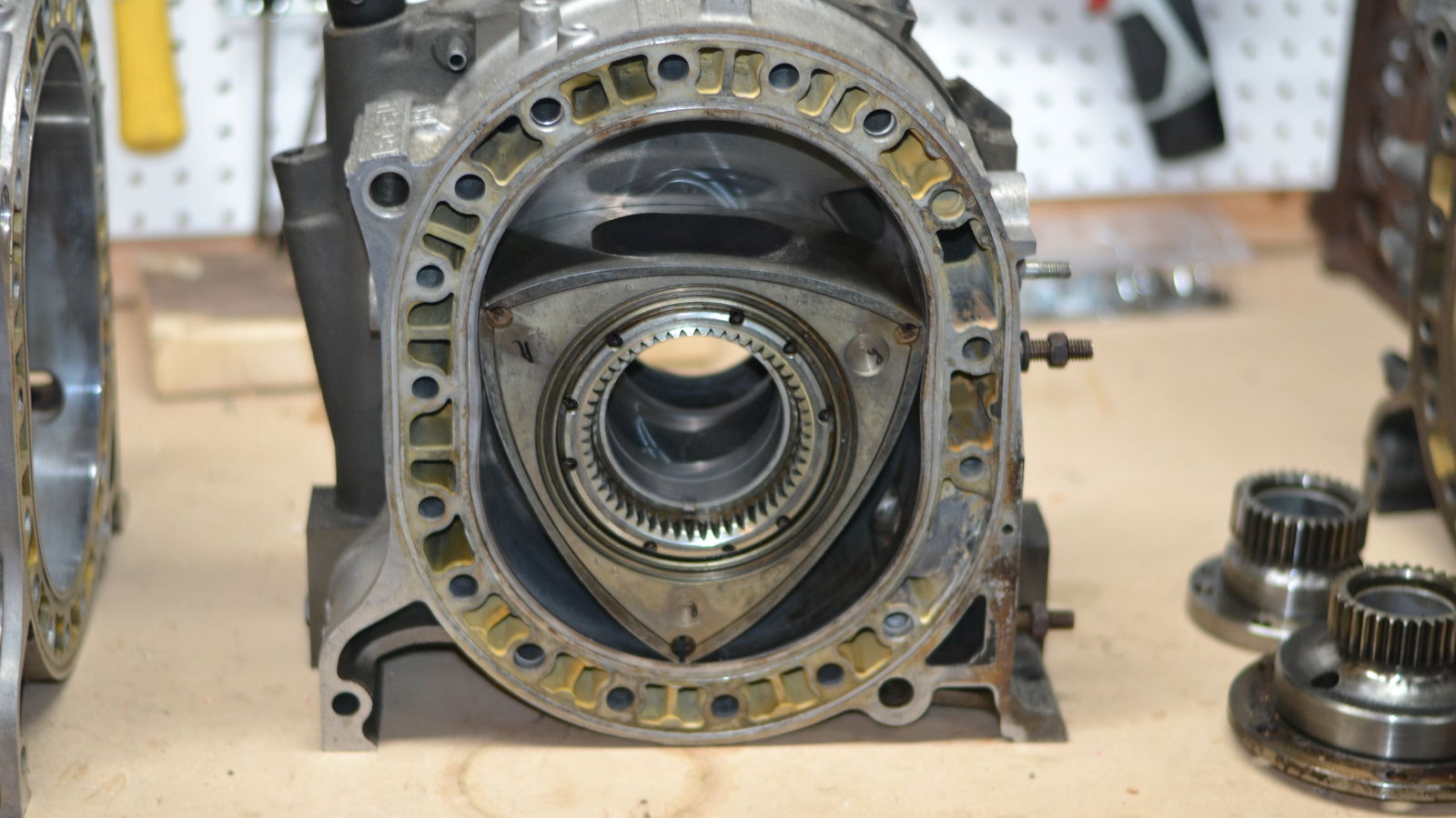

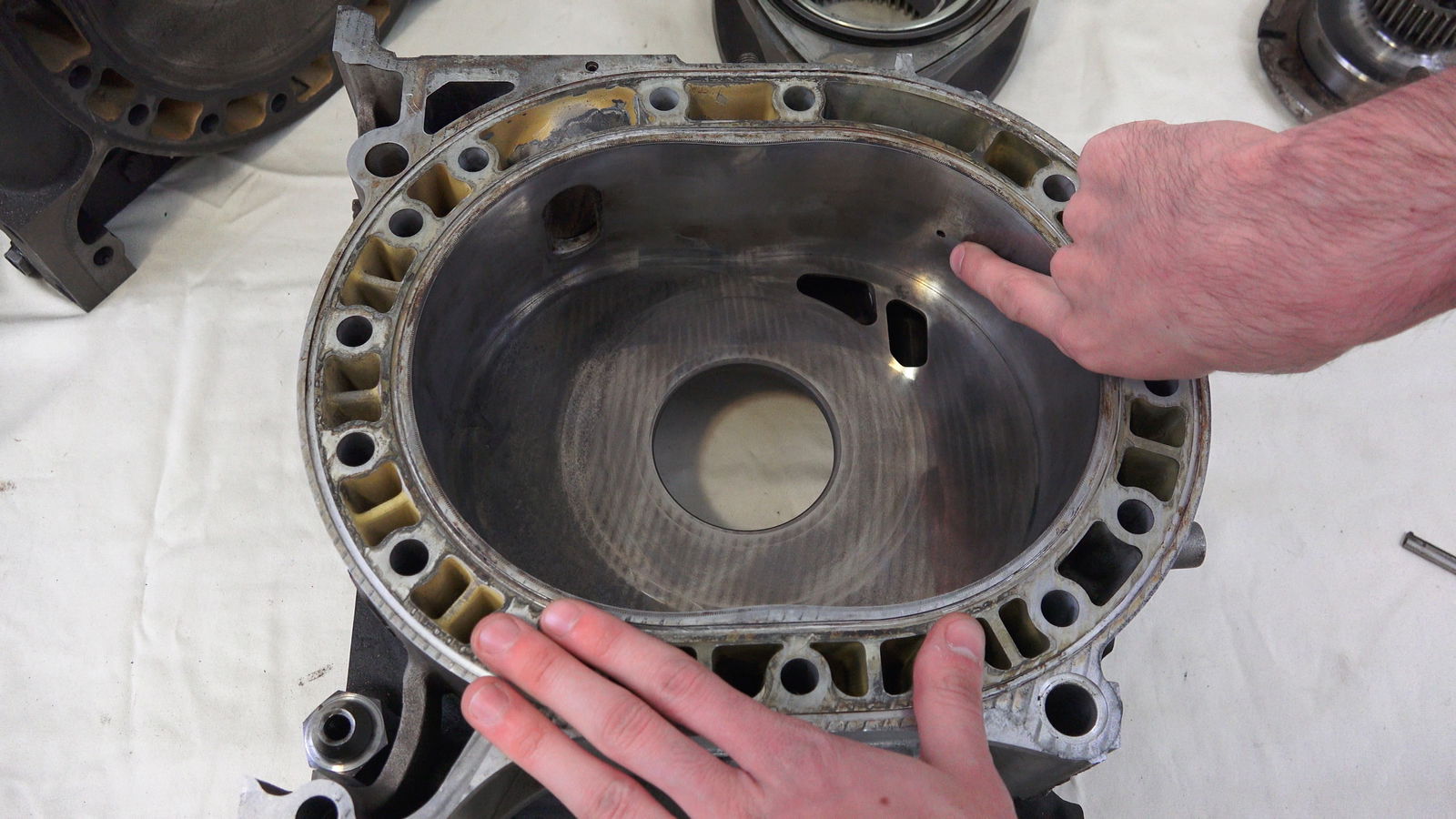

The process of the rotary engine is very similar to what occurs in a traditional piston cylinder engine. The difference is instead of pistons, there’s a triangular-shaped rotor, and instead of cylinders there’s a housing reminiscent of an oval.

Intake

As the rotor moves within the housing, a small pocket of air expands into a larger pocket, thus creating a vacuum. This vacuum is exposed to the intake ports, which air and fuel are then drawn from into the combustion chamber.

Compression

The rotor continues to rotate, compressing the air-fuel mixture against the flat side of the rotor housing.

Power

Two spark plugs are used to ignite the air-fuel mixture, helping to speed up the combustion process and ensure the majority of the fuel burns, and this forces the rotor to continue to rotate.

Exhaust

Similar to the intake stroke, the rotor moves until exhaust ports are accessible, and the exhaust gases at a high pressure are then forced out as the rotor closes off the housing.

What’s important to realise is that unlike in a piston cylinder engine, within a single rotor housing all of these events are occurring nearly simultaneously. This means that while intake is occurring on one portion of the rotor, a power stroke is also occurring, leading to a very smooth power delivery and a large amount of power in a small package.

2. What advantages does the Wankel engine have?

Weight-to-Power

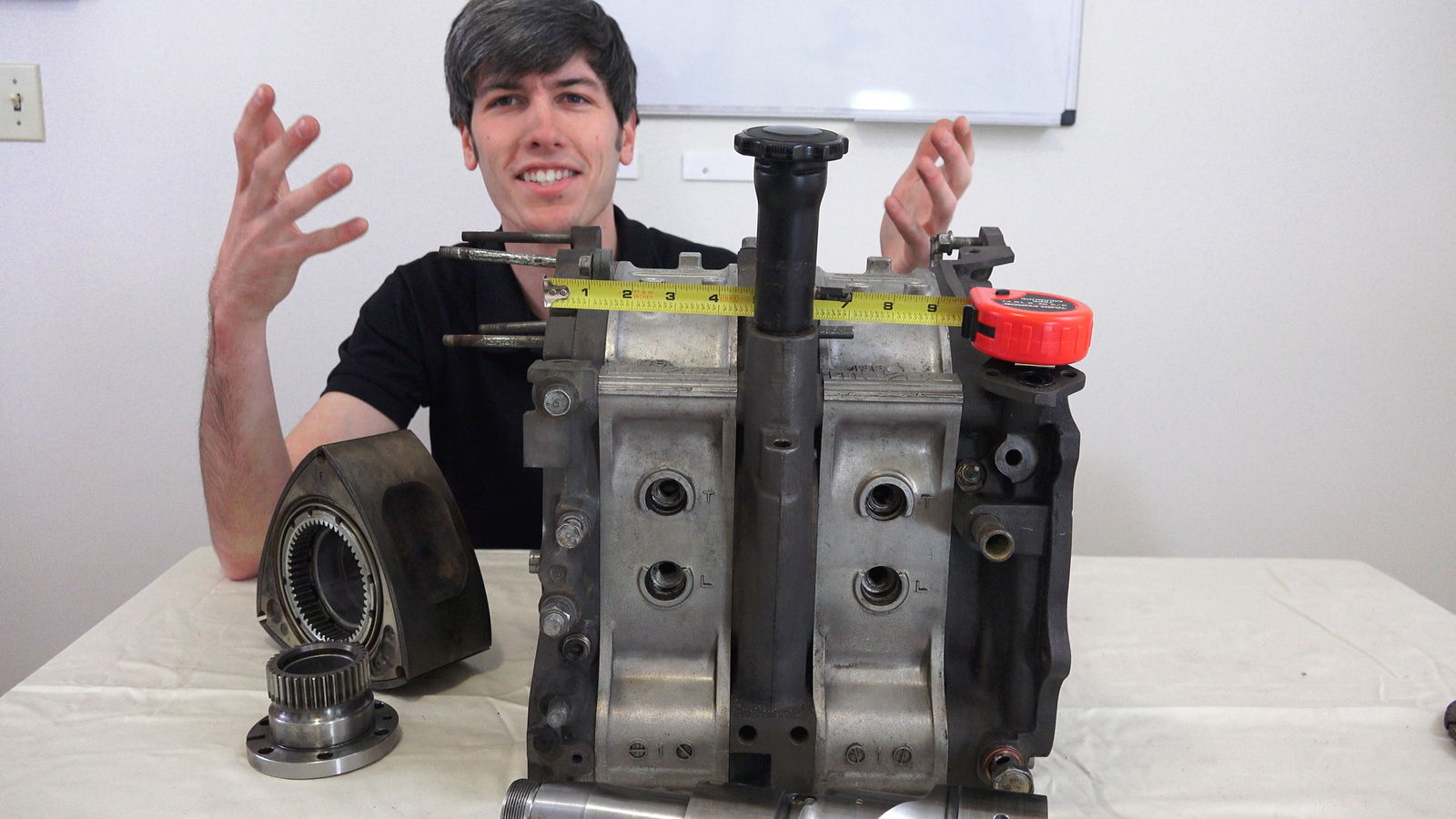

One of the biggest advantages of the rotary engine was its size. The 13B engine of the Mazda RX-7 took up about one cubic foot of volume, yet produced a significant amount of power for its small proportions.

Fewer Moving Parts

Often in engineering, the simplest solution tends to be one of the best solutions. The rotary engine drastically reduces the number of parts required for combustion to occur, with just three main components spinning in a two-rotor motor.

Smooth and High Revving

The rotary engine has no reciprocating mass, like valves or pistons in a traditional engine. This leads to an incredibly balanced engine with smooth power delivery, and the ability to rev high without concern of things like valve-float.

The 2011 Mazda RX-8 was the final production vehicle with a Wankel rotary, the 1.3-litre Renesis. Whether or not the RX-8 lived up to the rotary name, we all shed a tear at the loss of this innovative and unique approach to internal combustion. What dealt the final blow? The RX-8 was unable to meet Euro 5 emissions regulations, and thus it could no longer be sold in Europe after 2010. Though still legal in the states, sales had significantly dropped as the model had been around since 2004.

What disadvantages are there to the rotary design?

Low Thermal Efficiency

Due to the long and uniquely-shaped combustion chamber, thermal efficiency of the engine was relatively lower compared to piston-cylinder counterparts. This also often led to unburnt fuel leaving the exhaust (hence the tendency of rotary engines to backfire, which is obviously as awesome as it is inefficient).

Burn Baby Burn

By design, the rotary engine burns oil. There are oil squirters in the intake manifold, as well as injectors to spray oil directly into the combustion chamber. Not only does this mean the driver must regularly check oil levels to keep the rotor properly lubricated, but it also means more bad stuff comes out the tailpipe. And the environment hates bad stuff.

Rotor Sealing

Another issue which also can impact emissions: it’s challenging to seal the rotor when it’s surrounded by vastly different temperatures. Remember, intake and combustion are occurring simultaneously, but in very different locations in the housing. This means that the top of the housing is relatively cool, while the bottom of the housing is much hotter. From a sealing standpoint, this is problematic, as you’re trying to create a metal-to-metal seal with metals which are operating at significantly different temperatures. By using coolant jackets to help even out the heat load, this problem can be reduced, but never fully diminished.

Emissions

When you put it all together, emissions killed off the rotary. The combination of inefficient combustion, inherent oil burning, and a sealing challenge result in an engine that’s not competitive by today’s standards on emissions or fuel economy.

How does the RX-8 stack up against competitors?

In my video describing the drawbacks of the RX-8, viewers rightfully pointed out that I compared model year 2015 vehicles to a 2011 model in terms of fuel economy, which was unfair on Mazda’s end. Let’s right this wrong, using the RX-8’s first model year.

| Car | Engine Size | Weight | Power | MPG Combined Rating |

| 2004 Mazda RX-8 | 1.3L Wankel | 3053 lb (1385 kg) | 197-238 HP (Auto/Man) | 18 mpg (13L/100km) |

| 2004 VW GTI | 1.8L I4 | 2934 (1330 kg) | 180 HP | 24 mpg (9.8L/100km) |

| 2004 Corvette | 5.7L V8 | 3214 lb (1458 kg) | 350 HP | 20 mpg (11.8L/100km) |

As you can see above, the RX-8 doesn’t stack up favourably in terms of fuel economy. The Corvette, with a significantly larger engine, 47 per cent more power, and five per cent more weight still manages 11 per cent better fuel economy. It’s also worth mentioning that this was the first model year for the RX-8, while the Corvette and GTI engines had been around from previous years. Quite simply, there’s nothing good to say about the RX-8 in terms of fuel economy. Although the buyer may not necessarily view this as a negative point, without passing emissions there is no car to buy.

It’s worth noting that since the original publishing of this article, Mazda has announced it will bring back rotary engines, although only as small range extenders in electric vehicles. In other words, nothing that will go ‘braap’.

Comments

There must be a way of correcting this low economy ratio. Perhaps if someone managed to drain all of the unburnt fuel in the exhaust, and reinject this fuel to the engine, we could save a lot of fuel, thus even improving emissions.

The Rotary is the best engine performance wise. You just can’t beat the power to weight ratio and the small size of it. I still have hope that the RX-Vision reaches a production version and see the Rotary roam the streets once again!

Neither does it have to comply with emission standards.

Just do like Chevy etc, build crate motors and sell to dragsters/drifters/restomods.

That will keep the rotary alive without having to conform with emission standards in newer car designs.

I agree the thermal efficiency is the major challenge in rotary engines generally. There are new technologies we have developed to overcome these challenges. unlike the mazda engine, these technologies don’t use oil to cool the rotor. You can get more details on these technologies at: http://www.aieuk.com/technologies/. You can follow us on http://www.twitter.com/aieukltd for any updates

B…but…but…brapbrapbrap….

surely with all these advances in technology since the renesis they could figure out how to make them more efficient?

Any comment about this modification: http://www.pattakon.com/pattakonPatWankel.htm ?

Mazda have done promising research on HCCI ignition for its SkyActiv-R rotary engine project using research from its SkyActive 2 program. They have removed the need to locate the spark plug outside the combustion chamber to allow the rotor to sweep past. Mazda solved this in the SkyActiv-R rotary project. Rotaries generally have high compression ratios giving the design’s easy adoption of homogeneous charge compression ignition (HCCI).

It looks like the next Mazda rotary will not have a spark plug and be HCCI ignition. Fuel consumption will match piston engines and when used as a constant speed generator, as in a hybrid car, outperform piston engines with all the advantages of low weight, small size, super-smooth, simplicity, etc. The expectation will be that the engine will be introduced in 2020, the 100th anniversary of Mazda. Looking good.

Rotaries are better suited to constant speed, high efficiency genset applications rather than direct drive via gearboxes. In that application piston engines cannot compete. Rotaries are better suited for series-hybrid cars being much superior than piston engines in that application.

The engine performs very, very well in fuel consumption and emissions running at a ‘constant speed’ turning a generator - its most efficient “sweet spot”. Wankels lose efficiency dramatically when they are revved up and down as when directly driving a car. The engine has a vastly superior power-weight ratio than piston/crank engines and is about one third of the size and weight of a piston engine for a similar power output.

All these positive attributes combine to make a superb range extender, when the traction wheels are turned by electric motors. If a car is plugged in each night and uses grid power to run most of the time, then wear on these units will be negligible. As the engine is only periodically used, the life of the engine is greatly extended. Also newer metallurgic techniques are being used to make the engines. Even when batteries are depleted, the Wankel can provide enough electricity to power the car and still be economical.

It takes only 25 to 30hp to propel a large American car down the highway at 70mph. Yet they put engines in them that can output 150 to 200hp. Most of that output is for acceleration and heavy loads. Highly inefficient. The great thing about a series-hybrid is that the generating engine works totally independent of the demands of the electric driving motor, enabling maximum efficiency when running. This means the generating engines can be greatly downsized. The battery acts as an energy buffer to give acceleration boosts.

The first ever series-hybrid plane flew in June 2013 - using a Wankel engine asa generator. This was of its small size and light weight. The plane had an electric prop. The makers say it can be scaled up to around a 100-150 seater plane. The Wankel engine(s) can be in the fuselage for better weight distribution (small and smooth) with small electric motors on the wings giving lighter, and cheaper, wings. About 5 companies around the world still make Wankel engines for special purposes such as drones.

The sooner they are introduced in road vehicles in series-hybrid form the better. The Wankel has finally met its niche.

Then you have the FAKE DISPLACEMENT of 1308 cc Mazda gave these 13B engines. Their MPG numbers take away its fake 1.3 liter displacement of 1308cc. Mazda just used one face or side of each rotor to count its volumetric efficiency, but give a spark or ignition to that sole side of each rotor Mazda counts and that triangular rotor won’t be able to complete a spin.

Each rotor side displaces 654 cc so the real displacement for the 13B is 3924 cc or 3.9L

Pagination