#TechTip: Commonly Overlooked Things When Installing Wheels

Wheels are simple right? Usually, there are 4 or 5 lug holes to line up, and you tighten the lug nuts and you’re done. This gets the job done, but here are some things you may not be aware of when installing your wheels.

Wheels are simple right? Usually, there are 4 or 5 lug holes to line up, and you tighten the lug nuts and you’re done. This gets the job done, but here are some things you may not be aware of when installing your wheels.

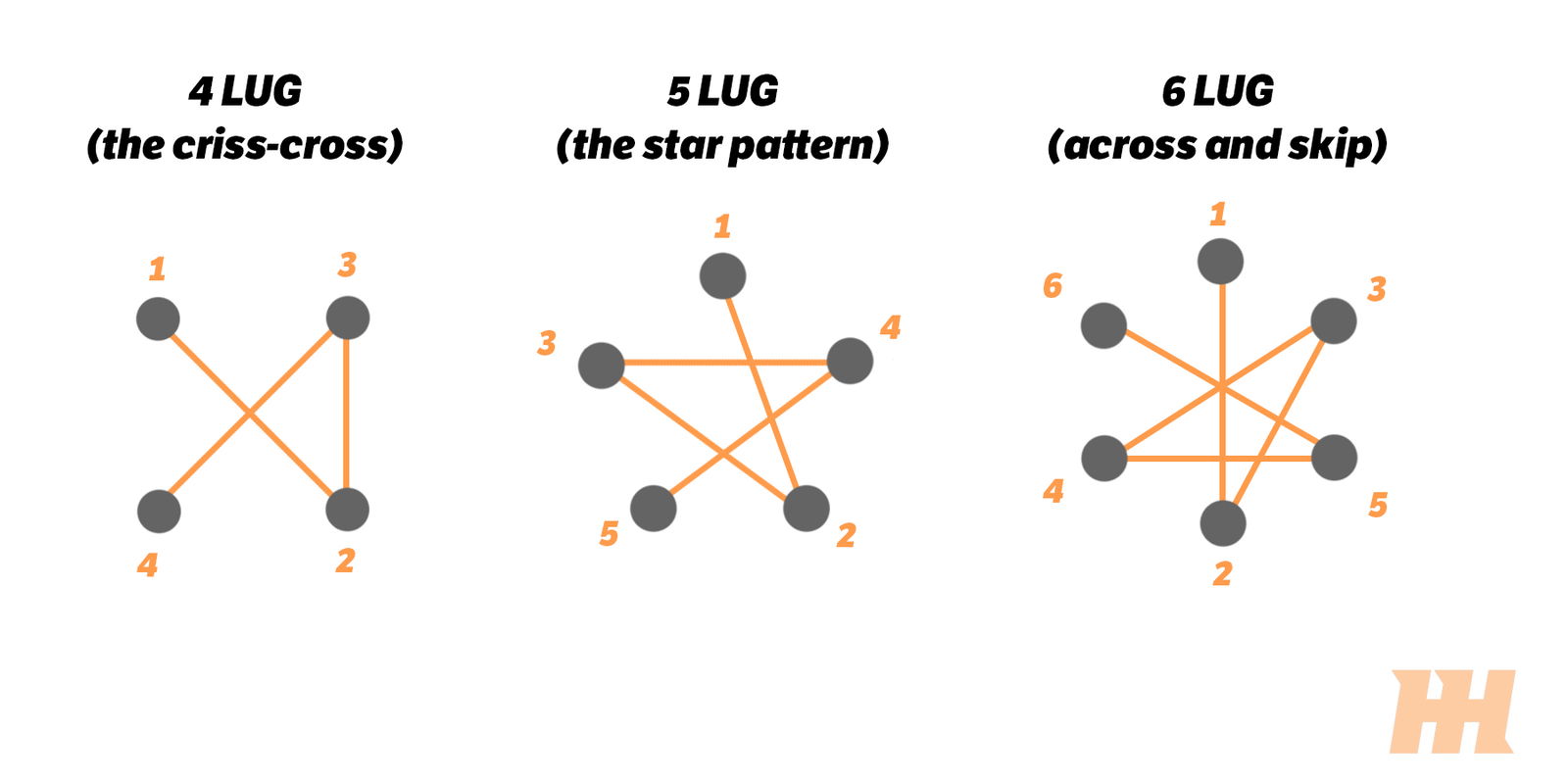

Tighten lugs nuts in the proper pattern

Every lug pattern has a specific tightening pattern required for tightening. This helps to securely and evenly tighten the wheel to the mating surface. Failing to do this can have negative effects on your wheel being centered, and can even warp your brake rotor. Proper torque sequences are as follows:

Keep the wheel centered

If you don’t have a hubcentric wheel (or adapter), make sure you’re rotating the wheel and tightening the lugs in a consistent location. This helps to center the wheel over the lugs, and it can reduce unwanted wheel vibrations while driving. If you’re not quite sure what a hubcentric wheel is, read more here.

Finger tighten lugs first

It’s easy to want to go right for the power tools, but this is the easiest way to mess up stud threads. Make sure you hand thread lug nuts before you start tightening them down. It’s best not to use power tools to over-tighten the lugs either. Repeated over-tightening can stretch studs, and will weaken them over time. Tightness is important, but a torque wrench is your best friend for tightening lug nuts to the factory spec.

Make sure you have enough thread for your lugs

When using aftermarket wheels, make sure you have enough threads for your lug nut to get a good grab. The general rule of thumb is being able to get a minimum of 6 rotations of the lug nut after you start tightening it. If you come up short, consider getting extended studs for maximum safety points.

Comments

Proud that I know all these little things from my father.

PROPER TORQUE ON ALUMINUM WHEELS!!!

How about: make sure you use a torque wrench?

The problem I come across when telling guys that they’re tightening their wheel lugs incorrectly is that they feel offended to be corrected by someone else. You tell them to do something properly and they just respond with “what do you know?”, “I know cars man, I’m tightening the wheels correctly, i’m not stupid!”

It’s also good to remember to avoid at all costs mistaking a cone (taper) seat and ball (radius) seat lug nuts/bolts. A moron in the tyre shop ruined a oem wheel in my car doing that

I always get lug nuts to the wheel with a wrench (so that the wheel is secure) and then lower the car down, and hand tighten (I used to do it with a torque wrench, but i got used to the force and dont need it anymore when tightening wheels). I’ve seen messed up threads when someone uses power tools… pain to fix…

Another thing to note is stop using aftermarket alloy wheels nuts they strip way to easily and can cause corrosion if you need that extra 500g of weight saving go do a turd before driving

“rule of thumb is being able to get a minimum of 6 rotations of the lug nut after you start tightening it” its 7 in germany, btw. Probably because #Autobahn

Who didn’t already know this? Whats next make sure to check your oil on a level surface?

Great article. Also applies to trailers if you’re hauling, by the way. It gets even tougher once you get up to eight and ten lugs though.

Pagination