Why Wheel Bearings Are Important, And What Happens When They Fail

There’s a decent chance that at some point, you’ve had your car back from an MOT test and found a patch of orange on the results that says something along the lines of ‘play in offside front wheel bearing.’ It sounds scary - after all, in order of everything you want to function correctly on your car, the wheels are pretty far up the list.

As long as you catch a wheel bearing issue early, though, it shouldn’t be a massively expensive or time-consuming fix, and if you’re decent with a spanner, it’s potentially something you can sort yourself. Here’s what a wheel bearing is, why it’s important, and how to tell if there’s something wrong with one.

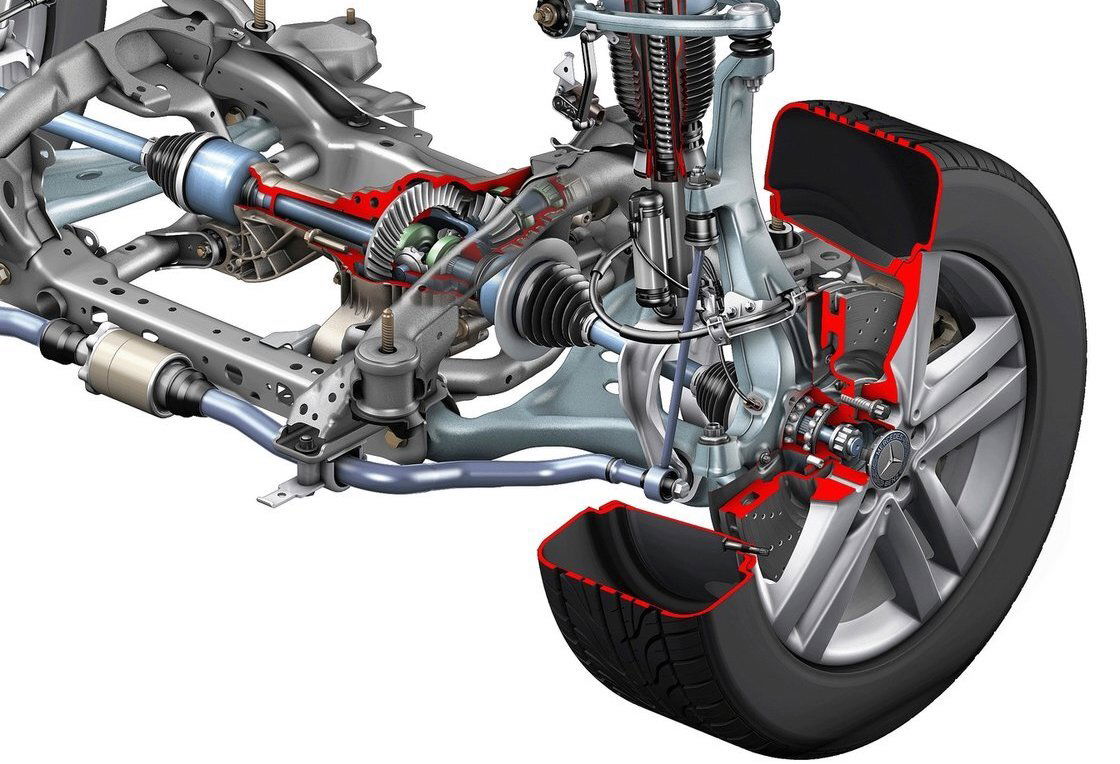

Wheel bearings play an important role within the drivetrain of any vehicle, as they provide the first connection between the moving and static areas of the car. A bearing – in its simplest form – is a friction reduction device placed within something like a wheel to aid the efficiency of rotation. This is achieved as rolling produces much less friction force than sliding.

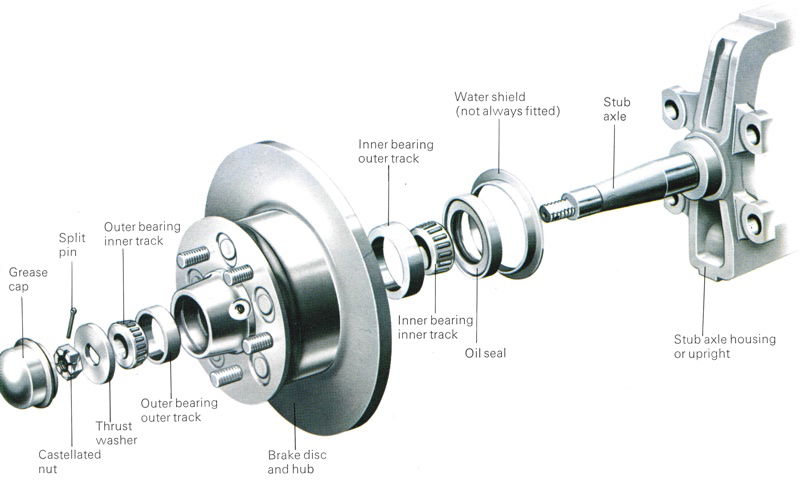

A car’s wheel bearing does this by using small metal balls or cylindrical rollers that roll between two smooth rings of metal. Helped along by grease, the bearing rotates in tandem with the wheel’s rotation, the rolling motion of the balls or rollers allowing the wheel hub to rotate as freely as possible. It also helps absorb some of the forces exerted on the car’s wheel during acceleration, braking and cornering.

The wheel bearing is housed within the hub assembly, providing the static connection with the hub carrier through an outer ring or ‘racer’. On driven wheels, the driveshaft travels from the transmission and passes through the centre of the wheel bearing through the inner ring, creating the rotational partnership. Ball-type bearings are generally used on the driven wheels of a vehicle, while tapered roller bearings, with cylindrical rollers arranged around an inner ring, are predominantly used on the non-driven wheels.

Like all mechanical parts on a car that rotates, rub and roll, they tend to wear out eventually. There are several signs of a knackered wheel bearing. The most common is a constant drone, hum or growl from the affected wheel, which will get more noticeable as speed increases or the car turns. You may also notice less responsive steering or speed-dependent wheel wobble. On more modern cars, which often have anti-lock brake sensors integrated into the hub assembly, you might get an ABS warning light on the dash.

There are three general causes of a dodgy bearing:

• Incorrect alignment due to poor installation

• A damaged or leaking bearing seal

• An inward collision due to a side impact

The most common mechanical failure is due to a seal leak, which allows the lubricating grease to exit the bearing, and water and grit managing to worm its way in. This all amounts to the degradation of the balls and the outer and inner housing of the bearing, often creating that gritty, skimming sound as the wheel is rotating. Looking inside a worn-out bearing, there will often be small specs of metal that have broken off from inside the bearing itself and are grinding their way around the racers, causing more damage. If you have had a minor shunt, it’s always worth having the hub assembly checked over afterwards.

Wheel bearings are generally made from hardened steel, so they can withstand a serious amount of rotational abuse. But apply heat (through lack of lubrication) or dirt and water (broken seal) and all hell can break loose (this is yet another reason to avoid driving through deep water). Hitting one too many potholes or taking speed bumps too quickly can also exert excessive force on your bearings, shortening their useful life.

To replace a wheel bearing properly, it has to be popped out of the hub assembly, preferably using a hydraulic press. Problems can arise with the re-installation of the new bearing, as the alignment must be accurate to avoid the bearing wearing out rapidly and causing further pain.

Wheel bearings should last tens of thousands of miles, but many mechanics will simply hammer the bearing back into the hub assembly instead of precisely aligning it and using the aforementioned press. This will inevitably lead to the bearing not rotating in the perpendicular fashion that it was designed for, accelerating wear and damage to the part. It’s important, therefore, if you’re not 100 per cent confident in your own ability, to ensure you’re using a trusted, professional garage.

Most online parts stores will now sell the entire hub assembly with the wheel bearing pressed into it, saving the hassle and potential scope for mistakes within the specific bearing assembly. It goes without saying, but you should also make sure that, if possible, you or the garage is using an original manufacturer part or one of reasonably similar quality - this is one area you really don’t want to skimp on.

If left to wear down further, a wheel bearing could seize and lock the axle, causing all sorts of additional damage to the drivetrain. Worst-case scenario, the wheel may come off the car altogether, so it’s best to get the car looked at as soon as possible if you suspect a dodge bearing. However, considering the forces that a drivetrain has to counteract during its lifetime of usage, it is impressive how long wheel bearings can last if inserted properly and looked after - depending on the car, original bearings can generally last for comfortably over 100,000 miles.

Although it can be a labour-intensive job if one were to fail, the shift to selling entire hub assemblies should make a bad wheel bearing fixable from home, with a decent tool kit and a bit of know-how. So do not fret the next time that horrid whir begins to creep into the cabin, as a fix may be only a ratchet spanner away.

Comments

Literally just changed mine like 2 weeks ago

The implications of not getting these fixed, doesn’t bare thinking about.

Wheel bearing for my 05 Audi A4, €250,- per wheel 0_0

Doing 100 kph in a volvo 240 With barely any front Springs on a bumpy road without front left wheelbearing.. Now that’s a thrill!

It’s also a common thing that the wheel falls off completely when the bearing fails.

Pagination